3Dresyn Bioflex A60 MF Monomer Free

Highly flexible biocompatible monomer-free 3D printing resin

Product description

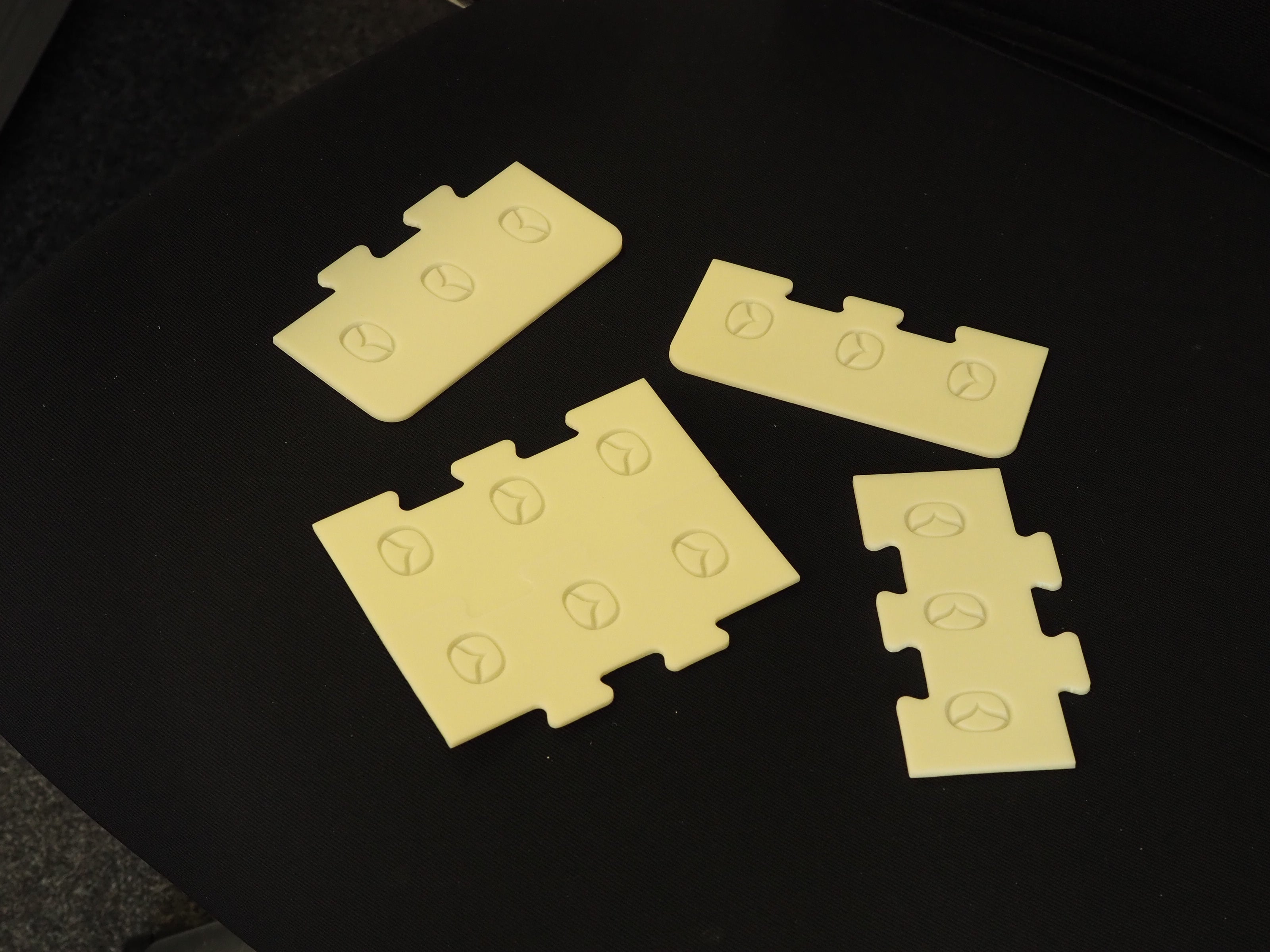

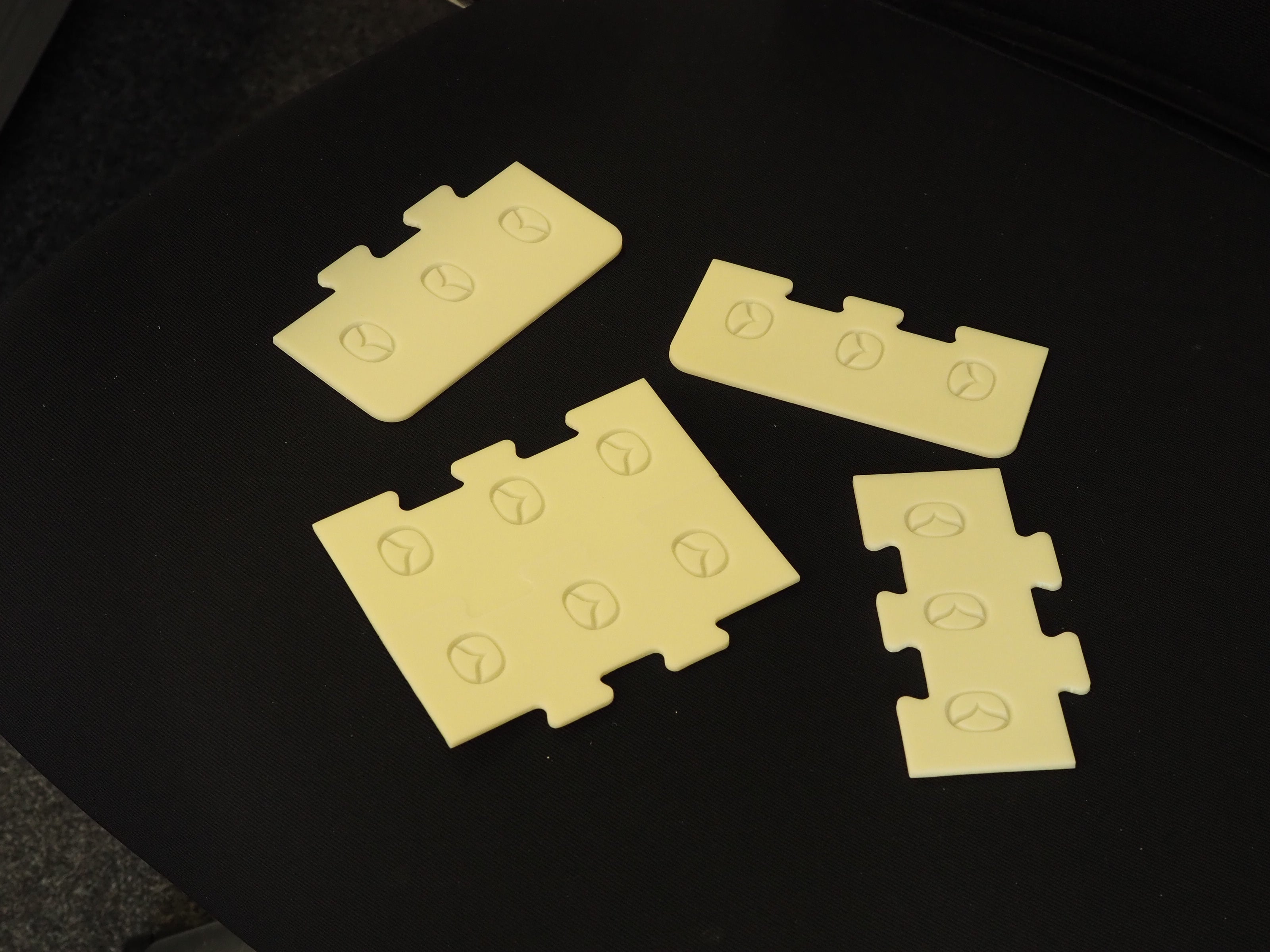

3Dresyn® Bioflex A60 MF is a highly flexible biocompatible monomer-free photopolymer resin designed for applications requiring softness, elasticity and comfort.

Intended use

Intended for professional use in vat photopolymerization (SLA, DLP and LCD) additive manufacturing.

Typical applications

-

Soft medical components

-

Patient-contact flexible parts

-

Cushions, seals and soft interfaces

Material properties & test methods

Mechanical properties

-

Shore hardness: A60 (ISO 868)

-

Tensile strength: ~ 2–6 MPa (typical) (ISO 527-1 / ISO 527-2)

-

Tensile modulus (Young’s modulus): ~ 1–5 MPa (typical) (ISO 527-1 / ISO 527-2)

-

Elongation at break: ~ 150–250 % (typical) (ISO 527-1 / ISO 527-2)

Thermal properties

-

Heat deflection temperature (HDT): < 40 °C @ 0.45 MPa (typical) (ISO 75)

Physical properties

-

Density: 1.0–1.2 g/cm³ (typical) (ISO 1183)

-

Water absorption: < 0.1 % (typical, 24 h @ 23 °C) (ISO 62)

Biocompatibility & regulatory framework

-

Biocompatibility evaluated according to ISO 10993

-

Manufacturing aligned with ISO 13485 quality management systems

Testing & processing disclaimer

Material properties are measured on printed and post-processed specimens and may vary depending on the selected material version, printer type, printing parameters, build orientation, post-curing conditions and test specimen preparation. Reported values are indicative and provided for reference only.

Printing & processing guidelines

-

Printing technologies: SLA, DLP and LCD

-

Wavelength range: 385–405 nm

Product units

-

Available units: 500 g, 1,000 g

Why choose 3Dresyn® Bioflex A60 MF

-

Very high flexibility and softness

-

Suitable for patient-contact parts

-

Monomer-free biocompatible formulation

Choose options