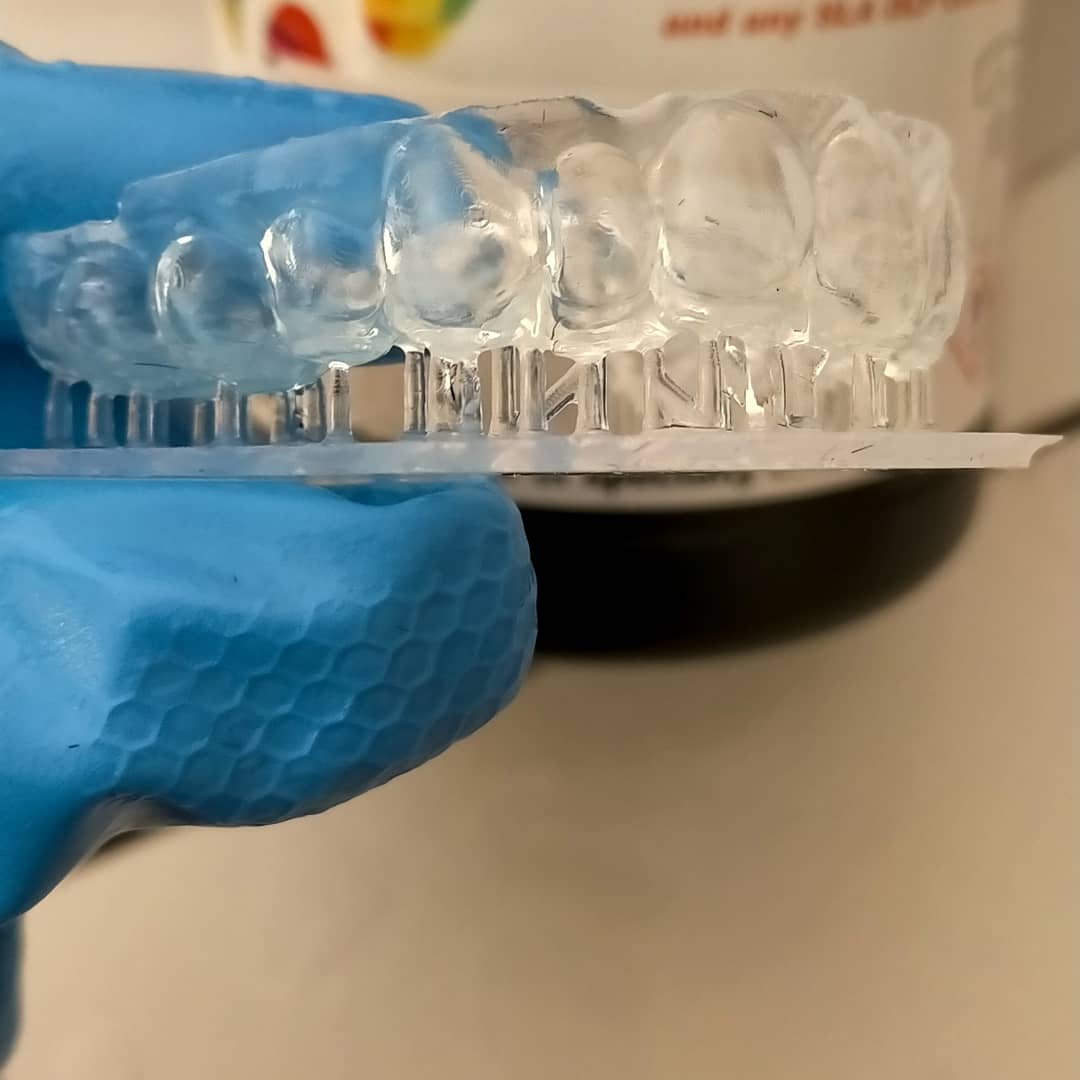

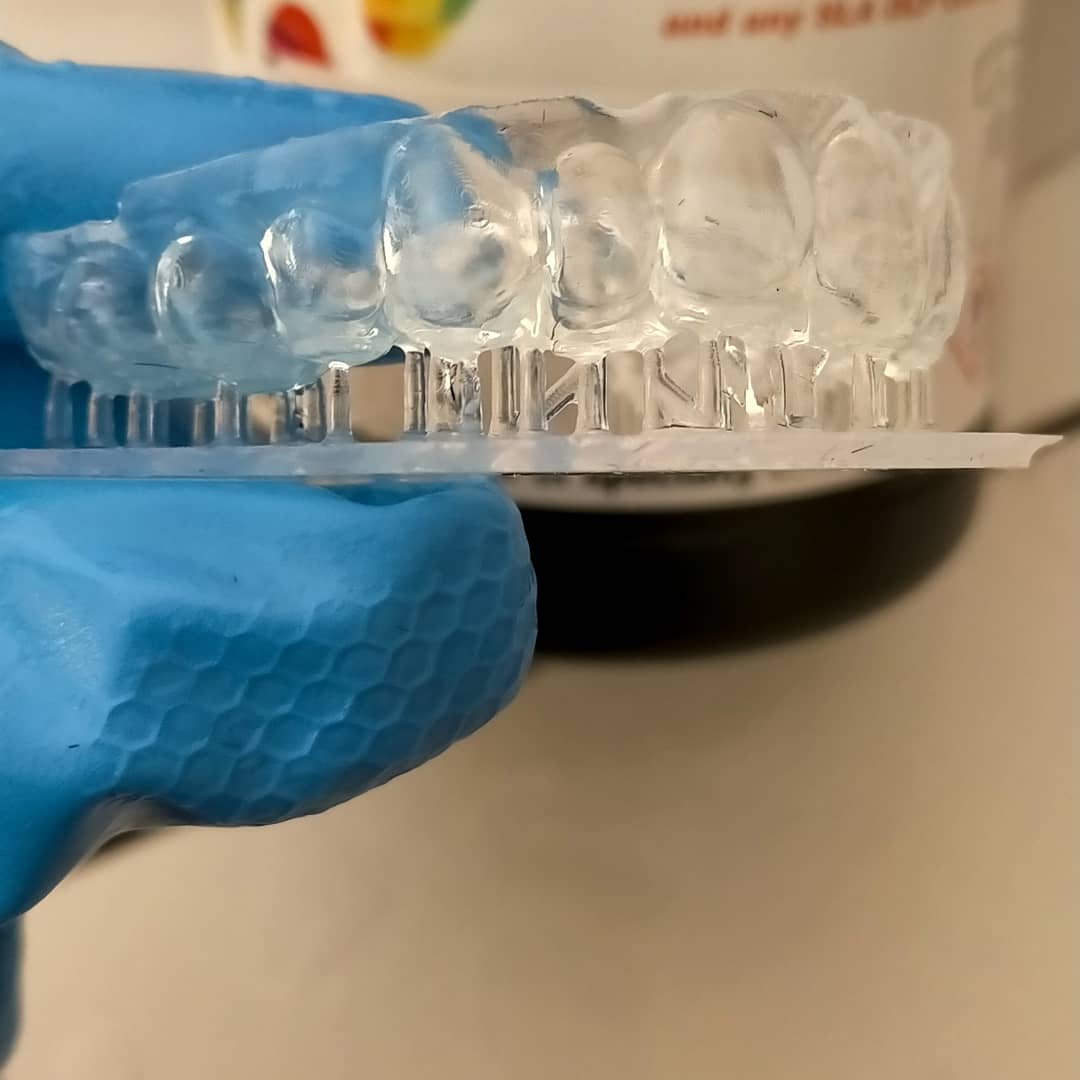

3Dresyn OD-Clear BIO for rigid night guards & surgical guides

Rigid clear dental resin for surgical guides and night guards

Product description

3Dresyn OD-Clear BIO is a rigid, transparent biocompatible dental photopolymer resin designed for the production of clear night guards and surgical drill guides requiring high mechanical strength, dimensional accuracy and durability during clinical use.

Intended use

Intended for professional use in vat photopolymerization (SLA, DLP and LCD) additive manufacturing for dental applications such as surgical guides and rigid night guards.

Final suitability of printed parts must be validated by the user according to the specific clinical application, processing conditions and applicable regulatory requirements.

Typical applications

Dental surgical drill guides

Implant placement and positioning guides

Clear rigid night guards

Dental appliances requiring high rigidity and transparency

Material properties & performance requirements

Measured mechanical properties

Shore hardness: D85 (ISO 868)

Flexural strength: > 80 MPa (ISO 178)

Tensile strength: > 40 MPa (ISO 527-1 / ISO 527-2)

Elongation at yield: < 3 % (ISO 527-1 / ISO 527-2)

Young’s modulus: 2000–2500 MPa (ISO 527-1 / ISO 527-2)

Functional and clinical performance

High rigidity suitable for surgical guide and rigid dental appliance applications

Resistance to deformation under drilling, biting and handling forces

High dimensional accuracy and stability during clinical use

High durability with resistance to cracking and mechanical fatigue

Optical and surface performance

Excellent optical clarity suitable for visual inspection and clinical visibility

High printing resolution up to 20 microns

Surface quality suitable for post-processing and polishing

Thermal, pressure and chemical resistance

Excellent resistance to heat and pressure during clinical use

Compatible with standard dental cleaning and disinfection workflows, depending on the validated process

Processing and handling performance

Very low viscosity for improved printability and resin flow

Very low shrinkage supporting dimensional accuracy

Printable on most commercial and professional SLA, DLP and LCD 3D printers

Increased durability of the resin tank

Water sorption and solubility

Water sorption (ULWA): ≤ 32 µg/mm³ (ISO 20795-1)

Water solubility: ≤ 1.6 µg/mm³ (ISO 20795-1)

Chemical safety indicators

Organo-tin free

Residual monomer content: < 0.1 %

Biocompatibility & regulatory framework

Biocompatibility evaluated according to ISO 10993

Designed to comply with ISO 20795-1 requirements where applicable

Manufacturing aligned with ISO 13485 quality management systems

Developed to meet applicable FDA quality and safety requirements, depending on the intended application

Testing & processing disclaimer

Material properties are measured on printed and post-processed specimens and may vary depending on printer type, printing parameters, build orientation, post-curing conditions and test specimen preparation. Reported information is provided for reference only.

Printing & processing guidelines

Printing technologies: SLA, DLP and LCD

Wavelength range: 385–405 nm

Post-processing: wash and post-cure according to a validated dental workflow for the intended application

Product units

Available units: 500 g, 1,000 g

Choose options