3D printing of sensors for biomedical applications offers advantages such as rapid fabrication, accessibility, and the ability to process a wide range of materials, including biocompatible and sustainable options.

Sensors used for monitoring have been implemented in robotics and industrial automation, aeronautics and aerospace, and in wearable sensor systems used as biomedical devices to analyse physiological parameters. They are also used in manufacturing to detect and monitor changes in the environment.

Limitations of conventional silicon-based sensors for biomedical use

Silicon-based sensors have traditionally been used as semiconducting sensors for monitoring industrial and environmental non biomedical applications, including micro and nano-sensors. Their main disadvantage lies in their non-biocompatible nature, which makes them unsuitable for many biomedical applications. Fully biocompatible sensors are required for biomedical and implantable applications.

3D printed semiconducting sensors: materials and opportunities

For flexible sensors, a wide range of processing materials can be used to fabricate prototypes for different applications. 3D printed resins or polymers containing carbon nanotubes (CNTs), graphene, and gold nanoparticles can be custom designed to print sensing electrode prototypes. Prototypes can also be custom designed with different 3D resin compositions and electrodes to meet specific electrical, mechanical, and thermal properties.

Fabrication of sensors by 3D printing permits fast and easy customisation and can require fewer steps than conventional techniques like photolithography or screen printing. 3D printed sensors can also be durable and exhibit strong mechanical performance. Additional advantages are simplicity, speed, automation, low waste generation, and risk mitigation.

3Dresyns capabilities for 3D printed biosensors

The 3Dresyns team has the expertise to custom design 3D resins for printing biosensors with these features and benefits:

- Excellent mechanical properties with tensile strength up to 70 MPa or higher

- Excellent printability on SLA, DLP, LCD, and Inkjet printers

- Engineering, biomedical, and elastic grades

- Monomer free biocompatible functional materials with no pictograms

- Tough, flexible, soft, and elastic grades

- Elongation <1-10% and up to 100%

- Durable

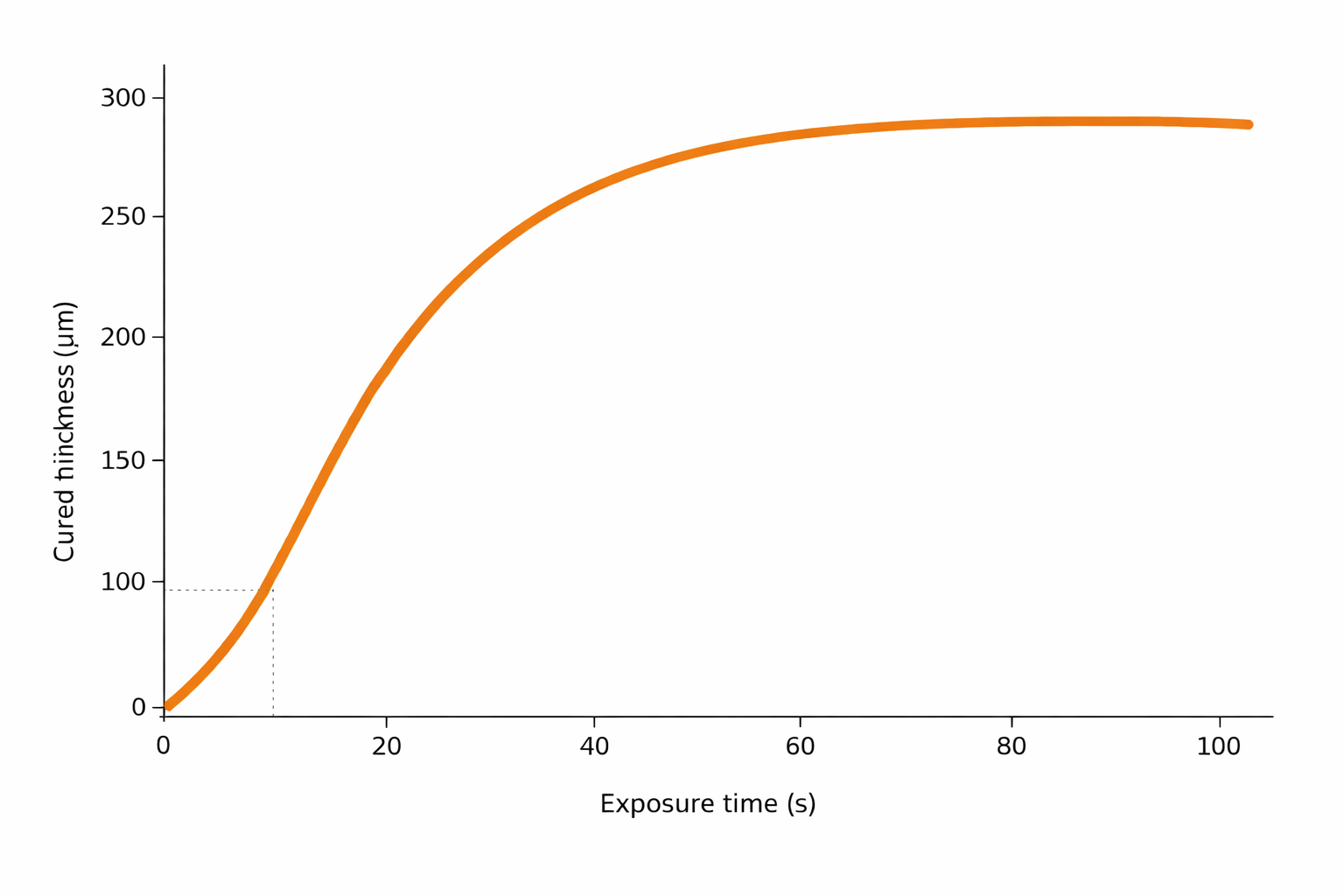

- Very high resolution

- Very low shrinkage

- Organo-tin free

Examples of physiological parameters

3D printed bio sensors can be custom designed to measure physiological parameters such as:

- Brain activity

- Blood pressure

- Heart rate

- Skin temperature

- Etc.

Nano and micron materials integration

Our capabilities include the incorporation, wettability, dispersibility, and stabilisation of a broad range of nano and micron particle size materials, in both powder and/or liquid form of different polarities, from hydrophilic (polar) to hydrophobic (non polar), in our specific custom designed SLA, DLP, LCD and Inkjet 3D resins, as the ones highlighted in the following review:

Contact

Contact us to consult about our 3Dresyns for Biosensors and your specific performance goals at: info@3Dresyns.com