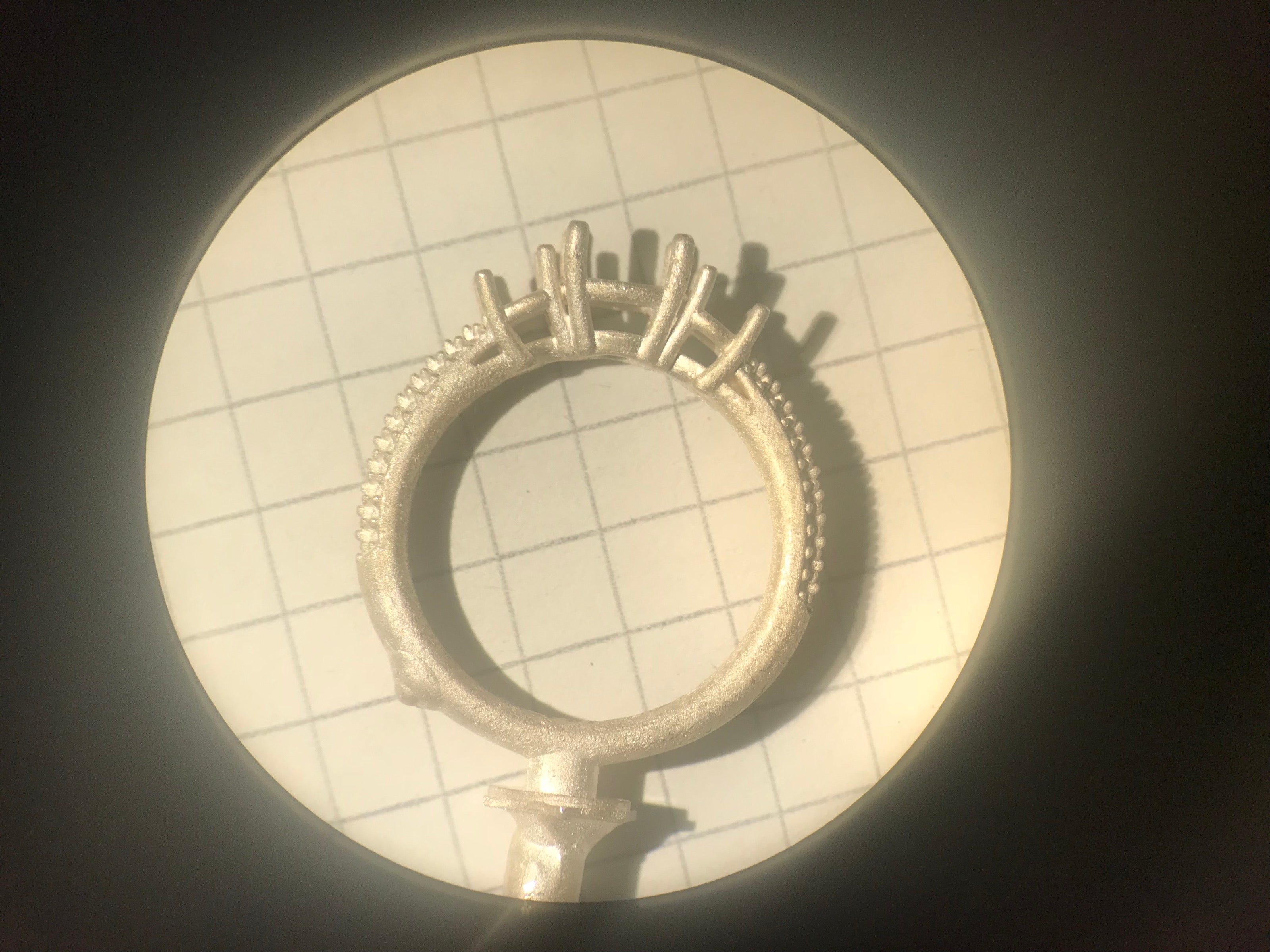

3Dresyn Perfect Cast LPP for Low Power SLA, DLP & LCD Printers

Sale priceFrom €130.00

3Dresyn Perfect Cast HPP for High Power SLA, DLP & Monochrome LCD Printers

Sale priceFrom €130.00

3Dresyn Perfect Cast WS1 Water Soluble for SLA, DLP & LCD Printers

Sale price€300.00