Instructions for Use (IFU) & Printing Parameters for DLP & LCD printers

These Instructions for Use (IFU) and Printing Parameters define general processing principles, qualified reference parameter windows, calibration methodologies, and user responsibilities for 3Dresyns® photopolymer resin systems used in vat photopolymerization technologies, focusing on projection-based DLP & LCD (including MSLA) systems.

3Dresyns materials are multivariable photopolymer systems. Final part properties are not intrinsic constants of the liquid resin, but depend on the complete material–printer–process–post-processing system, including printer optics, real light power, exposure strategy, printing temperature, washing chemistry, drying conditions, post-curing wavelength/power/time, and optional fine tuning.

Final part performance, safety and application suitability depend on strict adherence to qualified workflows. Deviation from these instructions may significantly affect mechanical behavior, surface quality, functional performance and long-term stability.

1) Scope, limitations & responsibilities

Scope of application

This document applies to photopolymer resin systems processed by vat photopolymerization technologies using DLP, LCD & MSLA exposure systems.

These instructions describe general methodologies and reference workflows and do not replace:

- printer-specific IFU supplements,

- application-specific validation required by the user,

- regulatory qualification required by the user/device manufacturer.

Limitations

This document provides qualified reference parameter windows and scientifically validated calibration principles. It does not replace user-side validation. Users remain responsible for verifying suitability for their specific printer, application, and regulatory context if applicable.

2) Material system and version control

3Dresyns® photopolymer resins are supplied as system-based materials that may exist in multiple formulation versions, viscosities, colors and functional configurations.

Users must verify that the selected resin version, lot number and associated documentation correspond to the intended printer technology and application.

Mixing versions or modifying formulations outside qualified workflows may invalidate expected performance.

3) Printer compatibility and exposure technologies

Vat photopolymerization includes different exposure architectures that require technology-specific workflows.

- Projection-based systems (DLP, LCD & MSLA) expose entire layers simultaneously.

Workflows, exposure strategies and fine-tuning approaches must not be transferred between different printer models, optics, or exposure configurations without re-evaluation.

4) Printing Parameters (qualified reference starting points)

Printing parameters directly affect:

- printing speed,

- XY resolution,

- Z resolution and dimensional accuracy,

- mechanical behaviour,

- peel force and print reliability,

- surface quality.

Optimisation is a controlled trade-off between speed, resolution, precision, and dimensional accuracy.

Record keeping (minimum)

For traceability and reproducibility, document at minimum:

- Resin name + version/viscosity/color/additives (if any) + lot number

- Printer model + exposure architecture (DLP/LCD/MSLA) + wavelength

- Real measured light power (if possible), exposure strategy, and layer height

- Orientation + support strategy (density, tip size, contact points)

- Washing chemistry + time + temperature

- Drying method/time

- Post-curing wavelength + power + time (and atmosphere if relevant)

- Ambient conditions (temperature/humidity) and any thermal steps

5) Standard starting printing parameters (quick baseline)

These values are practical starting points and must be validated for each resin system, printer and application:

- Z layer (slice) thickness: typically 50–100 µm (0.05–0.10 mm).

-

Normal exposure time per layer:

- Fast resins: typically 1–10 s

- Slower or highly filled resins: typically 10–20 s

- Bottom / adhesion layers: typically 2–4 layers at 75–100 s (adjust if needed).

- Z lift & retract speed: low / medium / high (usually non-critical).

- Light-off delay: 0.1–0.5 s.

- Z lift distance: 5–10 mm.

- Printing temperature: viscous resins may be warmed to 30–35 °C.

6) Why exposure times are printer-specific

Generic exposure times are approximations and cannot guarantee reproducible results because:

- light power varies across the vat,

- light output decays with cumulative printer use,

- different resins require different curing energies,

- thicker layers require higher energy doses.

Recommended background reading:

- Power differences of DLP, LCD & MLCD printers and their consequences

- Unlocking the black box of resin 3D printing

7) The scientific solution: Curing Rate Table (CRT)

7.1 CRT concept

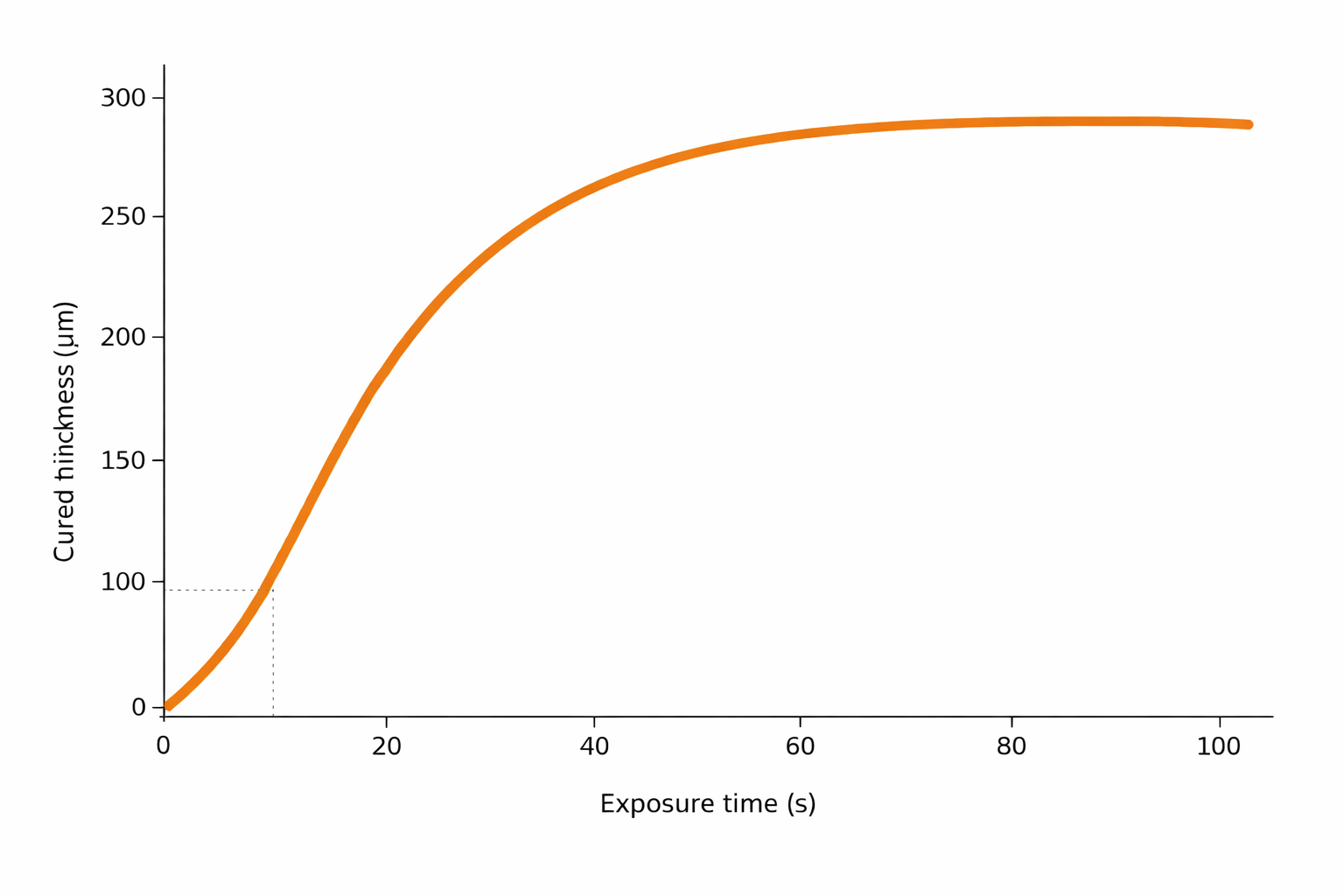

The Curing Rate Table (CRT) is a quantitative fingerprint describing how a specific 3D resin cures at a defined light power. It reports cured thickness (µm) as a function of exposure time.

A curing rate table establishes the relationship between exposure time and cured thickness for a given resin system under defined conditions.

Values shown in example tables are illustrative only and must not be used as universal settings.

7.2 Example of the Curing Rate Table (CRT) (reference format)

How do we fill up the Curing Rate Table? By measuring the thickness (in microns) of drops of the resin cured at 405 nm at different exposure times with a light power similar to your reported printer specifications.

Example of the Curing Rate Table (CRT) of a reference 3Dresyn x with lot y at certain light power of z mW/cm2 at 405 nm. The values shown are examples only.

| CURING RATE TABLE “CRT” | ||||

| Product & Lot | 3Dresyn x Lot y | |||

| Power: | z mW/cm2 at 405 nm measured with Chitu Systems Light Meter | |||

| Exposure time (seconds) | Thickness (microns) | Evaluation of cure (1) | Evaluation of adhesion on glass (2) | Starting point recommendations |

| 5 | 40 | 1 | 1 | |

| 10 | 120 | 2 | 1 | 1st starting exposure time for printing z layers of 100 microns (CRT) |

| 15 | 150 | 2 | 1 | |

| 20 | 195 | 3 | 2 | |

| 25 | 245 | 3 | 3 | |

| 50 | 270 | 4 | 3 | |

| 75 | 285 | 4 | 4 | Starting exposure time for printing 4 adhesion layers |

| 100 | 300 | 4 | 4 | |

| (1) Note: | 0 Non cured/ 1 poorly cured/ 2 medium cured/ 3 well cured/ 4 very well cured | |||

| (2) Note: | 0 Non adhered/ 1 poor adhesion / 2 medium adhesion/ 3 good adhesion/ 4 very good adhesion | |||

Starting point tip: Select your target layer thickness (e.g., 50 µm or 100 µm) and choose an exposure time where the CRT thickness is approximately ~1.2–1.5× the target layer thickness as a starting point. Under-cured (soft / weak) → increase exposure. Over-cured (excessive adhesion / brittle / loss of detail) → reduce exposure.

7.3 Practical calibration rule (fast method)

- Select target layer thickness.

- Choose exposure curing approximately ~1.2–1.5× layer thickness (starting point).

- Under-cured → increase exposure several seconds.

- Over-cured → reduce exposure several seconds.

7.4 Calibration procedure (spot timer method)

Step 1: Remove the build platform from the printer.

Step 2: Place a small resin drop on a clean glass slide.

Step 3: Position the glass slide at the center of the vat or tank.

Step 4: Expose the resin drop for a selected exposure time.

Step 5: Remove uncured resin and measure cured thickness using a caliper or micrometer.

Step 6: Record cured thickness and qualitative green strength.

Step 7: Repeat the procedure at increasing exposure times.

This procedure generates a curing rate curve specific to the resin, printer and exposure configuration.

7.5 Interpretation of curing behavior

Typical qualitative observations may include:

- uncured or weakly cured material at short exposure times,

- increasing cured thickness and strength with increasing exposure,

- overcuring at excessive exposure times, leading to brittleness or loss of detail.

The optimal exposure time corresponds to the desired balance between curing depth, adhesion and resolution.

7.6 Selection of starting print exposure settings (structured method)

As a general methodology:

- select an exposure time corresponding to approximately 1.2–1.5 cured layers as an initial reference,

- reduce exposure to increase speed and resolution,

- increase exposure to improve robustness if failures occur.

Bottom or burn-in layers should be selected based on the exposure time that produces the strongest adhesion under the same conditions.

8) Validation using reference test geometries (3Dresyns calibration tests)

8.1 Calibration step 1 — 3DTest1 (no supports)

This test evaluates:

- general printability,

- XY resolution,

- resin curing behaviour.

The smallest clearly resolved concentric ring indicates achievable XY resolution.

8.2 Calibration step 2 — 3DTest2 (with supports)

This test evaluates:

- XYZ dimensional accuracy,

- support behaviour.

Z accuracy may be calculated as:

Z error (%) = (measured − theoretical) / theoretical × 100

Example: printed thickness 2.1 mm vs nominal 2.0 mm → 5% Z-error.

9) Interpreting common failures (quick fixes)

- Detached part from build plate → increase bottom exposure and/or number of bottom layers.

- Soft or weak parts → under-cured → increase exposure.

- Brittle parts or excessive adhesion → over-cured → reduce exposure.

10) Optional fine tuning

3Dresyns resins can be optimised using Fine Tuning Additives to adjust printing speed, resolution, precision and dimensional accuracy.

11) Cleaning & post-processing requirements

Post-processing is an essential component of vat photopolymerization workflows.

Final properties depend strongly on:

- cleaning chemistry,

- cleaning time and temperature,

- post-curing wavelength, power and time.

Printed parts must undergo appropriate washing, drying and post-curing steps defined for the selected resin system and application.

Deviation from qualified post-processing workflows may significantly alter surface chemistry, mechanical performance and long-term stability.

For specific resin families, follow the dedicated documents:

- transparent workflows,

- coloured workflows,

- biocompatible workflows,

- conductive workflows,

- sacrificial workflows.

12) Handling, storage and contamination control

Resins and printed parts must be handled using appropriate protective equipment and contamination control measures.

Materials should be stored under controlled temperature, light exposure and humidity conditions. Cross-contamination between resin systems must be avoided.

13) Responsibilities of the user

Users are responsible for selecting appropriate materials, printers and workflows for their intended application.

Application-specific validation, regulatory compliance and final product qualification remain the responsibility of the user or device manufacturer.

3Dresyns does not assume responsibility for misuse, off-label applications or deviation from qualified workflows.

14) Governing principle

Vat photopolymerization materials are multivariable, system-dependent materials. Reported performance represents typical outcomes obtained under qualified workflows and is not an intrinsic property of the liquid resin alone.

15) Need professional support?

For printer selection, parameter definition or advanced optimisation, contact info@3dresyns.com or explore 3Dresyns technical consulting & support services.