Fast Instructions for Use (IFU) & Printing Parameters for Asiga DLP printers

This document provides fast, visual and practical guidance for the use of 3Dresyns® photopolymer resin systems on Asiga additive manufacturing platforms.

This Fast IFU for Asiga printers is intended as a visual reference and workflow aid and complements the official:

- Instructions for Use (IFU) & Printing Parameters for DLP & LCD printers

- Fast Instructions for Use (IFU) & Printing Parameters for DLP & LCD printers

- Instructions for Use (IFU) & Printing Parameters for Asiga DLP printers

The Fast IFU does not replace the official IFU and does not define validated or universal processing conditions.

Purpose of this Fast IFU

The purpose of this Fast IFU is to:

-

provide visual examples of typical Asiga Composer workflows

-

illustrate calibration steps and interface navigation

-

support faster onboarding and troubleshooting

Images, screenshots and examples shown in this document are illustrative only. User interfaces, firmware versions and available options may change over time.

Scope and limitations

This Fast IFU applies to selected Asiga systems and configurations used for vat photopolymerization.

Performance, print quality and material behavior depend on the complete material–printer–process system, including:

-

resin formulation and version

-

exposure power and strategy

-

post-processing workflow

-

environmental conditions

3Dresyns does not control printer hardware, firmware updates, user interface changes or proprietary exposure algorithms implemented by Asiga.

Users are responsible for:

-

verifying compatibility between selected 3Dresyns® materials and their specific Asiga configuration

-

validating final settings for their intended application

-

following the official IFU for all critical processing steps

Relationship to official Instructions for Use

In case of discrepancy between this Fast IFU and any official Instructions for Use (IFU), the official IFU always prevails.

The Fast IFU is provided for convenience, illustration and workflow orientation only.

Standard settings

- Z layer thickness: 0.050–0.100 mm (lower or higher can also be printable).

- Exposure time (typical range): ~2–20 s for 50–100 micron layers (depends on resin and power).

- Burn-In (typical): ~80 s is often enough for good adhesion for most resins.

- Important: Exposure times depend strongly on selected power (e.g., 7 mW/cm² is commonly the default in DentalMODEL). To find the optimum settings, fill the Curing Rate Table at your chosen power using the Spot Timer.

Printing (Asiga Composer workflow)

Open Asiga Composer and click NEW:

- Select your exact printer model and z layer thickness (most common: 0.050 mm or 0.100 mm).

- Select DentalMODEL (default) or any other material profile as a starting point:

Click “ADD PARTS”:

Add 3Dresyns 1st calibration file 3DTest1: the flat coin (no supports)

Click “BUILD WIZARD”:

Press NEXT

In the Build Wizard:

- Set Base Plate Thickness = 0.000 mm (during calibration, the flat coin is printed without base/supports).

- Leave anti-aliasing unchecked.

Use 80 seconds Burn-In exposure time for strong adhesion.

Leave Z and XY compensation = 0 during calibration.

The default Build Wizard exposure time (e.g., 2.5 s) must be replaced by the value obtained after filling the Curing Rate Table at your selected power (e.g., 7 mW/cm²) using the Spot Timer.

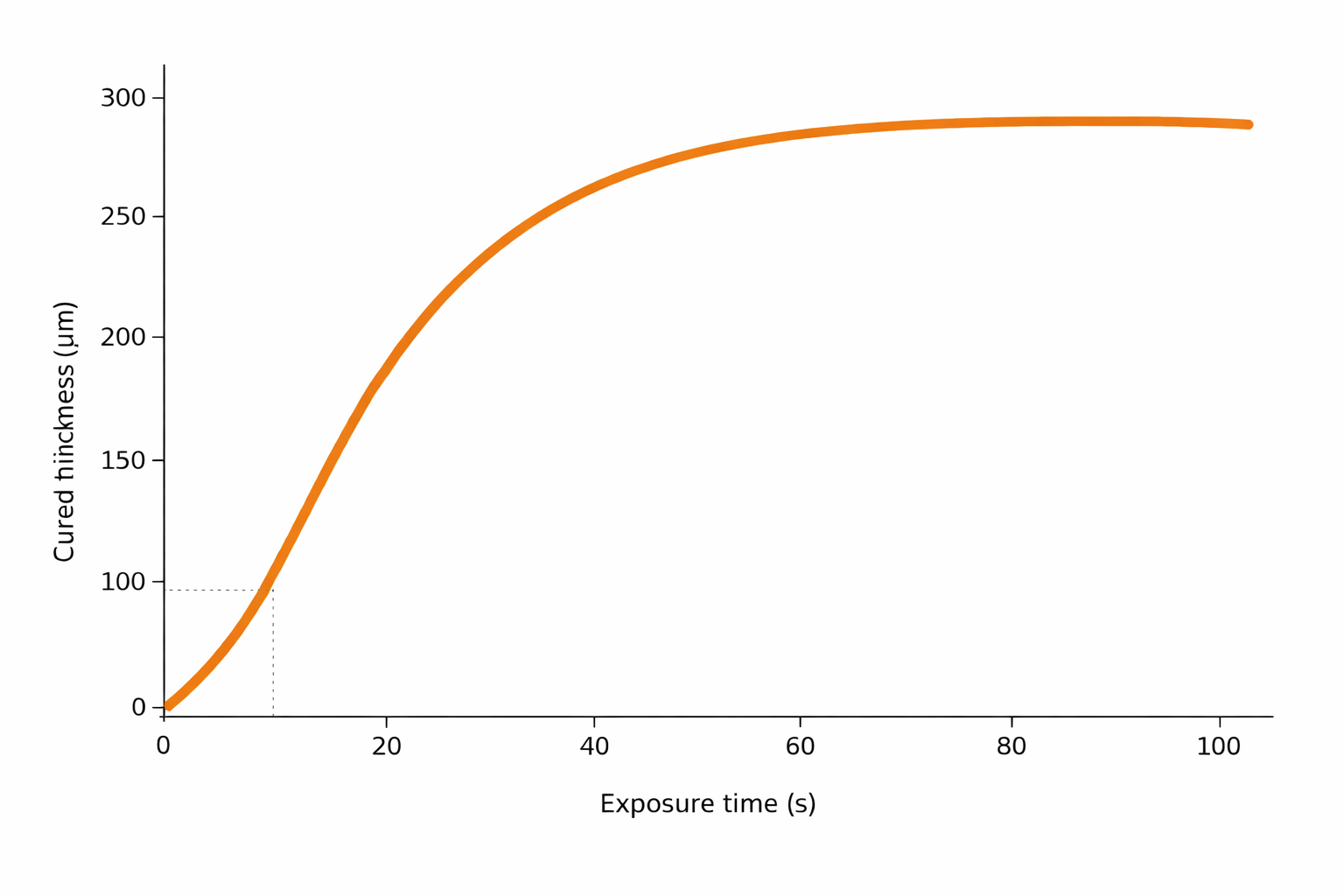

How to choose the optimum exposure time (Curing Rate Table)

This section describes a practical calibration method to determine suitable exposure times by correlating exposure duration with cured thickness and qualitative “green strength”.

Exposure behavior depends on resin formulation, exposure power, printer configuration and environmental conditions.

The values shown below are examples only. Users must generate their own measurements.

Curing rate table (example – user-generated)

Example of the Curing Rate Table (CRT) of a reference 3Dresyn x with lot y at certain light power of z mW/cm2 at 405 nm. The values shown are examples only.

| CURING RATE TABLE “CRT” | ||||

| Product & Lot | 3Dresyn x Lot y | |||

| Power: | z mW/cm2 at 405 nm measured with Chitu Systems Light Meter | |||

| Exposure time (seconds) | Thickness (microns) | Evaluation of cure (1) | Evaluation of adhesion on glass (2) | Starting point recommendations |

| 5 | 40 | 1 | 1 | |

| 10 | 120 | 2 | 1 | 1st starting exposure time for printing z layers of 100 microns (CRT) |

| 15 | 150 | 2 | 1 | |

| 20 | 195 | 3 | 2 | |

| 25 | 245 | 3 | 3 | |

| 50 | 270 | 4 | 3 | |

| 75 | 285 | 4 | 4 | Starting exposure time for printing 4 adhesion layers |

| 100 | 300 | 4 | 4 | |

| (1) Note: | 0 Non cured/ 1 poorly cured/ 2 medium cured/ 3 well cured/ 4 very well cured | |||

| (2) Note: | 0 Non adhered/ 1 poor adhesion / 2 medium adhesion/ 3 good adhesion/ 4 very good adhesion | |||

Starting point tip: Select your target layer thickness (e.g., 50 µm or 100 µm) and choose an exposure time where the CRT thickness is approximately ~1.2–1.5× the target layer thickness as a starting point. Under-cured (soft / weak) → increase exposure. Over-cured (excessive adhesion / brittle / loss of detail) → reduce exposure.

Calibration steps (spot timer method)

-

Remove the build platform from the printer.

-

Place a small resin drop on a clean glass slide.

-

Position the glass slide at the center of the vat or tank.

-

Cure the resin drop for a selected exposure time (e.g. 5 s).

-

Wipe away uncured resin.

-

Measure cured thickness using a caliper or micrometer and record qualitative strength.

-

Repeat the procedure at increasing exposure times (e.g. 10, 15, 20, 25, 30, 50, 75, 100 s).

This procedure generates a curing rate curve specific to the selected resin, exposure power and workflow.

Choosing your starting print settings

As a practical guideline:

- Select your target layer thickness (e.g., 50 µm or 100 µm) and choose an exposure time where the CRT thickness is approximately ~1.2–1.5× the target layer thickness as a starting point. Under-cured (soft / weak) → increase exposure. Over-cured (excessive adhesion / brittle / loss of detail) → reduce exposure.

Burn-In exposure should be selected based on the exposure time showing the strongest adhesion to glass, typically in the range of ~75–90 s.

Validation using reference test files

3DTest1 (flat coin without supports)

Confirms basic printability and provides an indication of XY resolution (smallest readable concentric circle).

If 3DTest1 fails:

-

Full detachment → increase burn-in time and/or number of bottom layers

-

Soft or tender part → increase standard exposure time (undercured)

-

Brittle part or excessive adhesion → decrease exposure time (overcured)

3DTest2 (flat coin with supports)

Validates printability with supports and enables evaluation of XYZ accuracy.

Example Z accuracy calculation:

If printed thickness = 2.1 mm and theoretical thickness = 2.0 mm

Z error (%) = (2.1 − 2.0) / 2.0 × 100 = 5%

Quality evaluation and fine adjustment

-

Read the smallest printed concentric feature to estimate XY resolution.

-

Measure printed thickness versus theoretical value to quantify Z accuracy.

-

If higher detail or accuracy is required, fine-tune exposure time, exposure power and/or use appropriate Fine Tuners following the applicable IFU guidance.

Basic tools and equipment

The following tools and equipment may be required to support setup, verification and post-processing when implementing printer-specific workflows on Asiga systems:

Tool selection and usage depend on the specific application and level of process control required.

Cleaning and post-processing

Cleaning and post-processing must follow the applicable Instructions for Use (IFU), including:

-

Any material-specific or application-specific IFU where applicable

Deviations from qualified post-processing workflows may affect surface quality, mechanical performance and long-term material behavior.

Technical support and consulting

For complex applications or advanced workflow optimization, technical support and consulting services may assist users in designing printer setups adapted to their specific requirements.

Technical consultation does not replace user responsibility for validation, qualification or regulatory compliance.

Advanced note for Asiga-specific optimization

Advanced workflow optimization on Asiga systems requires careful consideration of process trade-offs.

Increasing temperature may reduce resin viscosity and peeling forces, while increasing exposure power or light intensity may improve printing speed but can reduce resolution or surface definition.

Users implementing advanced optimization strategies are responsible for documenting final settings, maintaining traceability and validating performance for their intended application. Custom configuration files or printer profiles may be created as part of user-defined workflows. Record your final settings and, if needed, create your own INI file.