Fast Instructions for Use (IFU) & Printing Parameters for DLP & LCD printers

These Fast Instructions for Use (IFU) help you quickly identify optimum printing settings for 3Dresyns® using DLP & LCD 3D printers, with high reliability, consistency, and reproducibility. For deeper optimisation (full curing-rate workflow and extended troubleshooting), use the Detailed IFU.

This Fast IFU does not define validated or universal processing conditions.

1) Purpose of this Fast IFU

The purpose of this Fast IFU is to:

- support rapid printer setup and calibration,

- provide practical examples for exposure selection,

- assist troubleshooting during early printing stages,

- accelerate onboarding for DLP and LCD workflows.

This document focuses on speed, clarity and usability, not on exhaustive qualification.

2) Scope and limitations

2.1 Scope

This Fast IFU applies to:

- DLP and LCD vat photopolymerization printers,

- general-purpose, engineering and application-specific 3Dresyns® resin systems.

2.2 Not in scope

This Fast IFU does not apply to:

- laser-based SLA systems,

- inkjet, SLS or other non-vat technologies,

- regulated medical workflows unless validated separately.

2.3 System dependency

Performance, print quality and material behavior depend on the complete material–printer–process system, including resin version, exposure strategy, post-processing workflow and environmental conditions.

3Dresyns does not control printer hardware, firmware updates or proprietary exposure algorithms.

3) Standard starting settings for DLP & LCD printers (indicative)

These values are practical starting points and must be validated for each resin system, printer and application:

-

Z layer (slice) thickness: typically 50–100 µm (0.05–0.10 mm). Lower or higher layer heights can also be printable for most 3Dresyns.

Broader indicative range: 0.025–0.100 mm. -

Exposure time per layer:

- Fast resins: typically 1–10 s

- Slower resins: typically 10–20 s

- Bottom / adhesion layers: typically 2–4 layers at 75–100 s to ensure reliable adhesion to the build platform.

- Z lift & retract speed: low / medium / high (usually non-critical).

- Light-off delay / wait time: typically 0.1–0.5 s (usually non-critical).

- Z lift distance: typically 5–10 mm (usually non-critical).

- Printing temperature: warm viscous resins to ~30–35 °C before printing (protect from ambient light). Low-viscosity resins can be printed at room temperature.

4) Why exposure times are printer-specific

- Each printer has different light power across the vat (often higher in the centre than at the edges).

- Light power decays naturally with cumulative printer use.

- Different resins require different curing energies.

- Thicker layers require longer exposure times.

As a result, generic exposure times are only rough approximations and cannot guarantee reproducible results across printers and over time.

Recommended background reading:

- Power differences of DLP, LCD & MLCD printers and their consequences

- Unlocking the black box of resin 3D printing

5) The solution: Curing Rate Table (CRT)

5.1 CRT concept

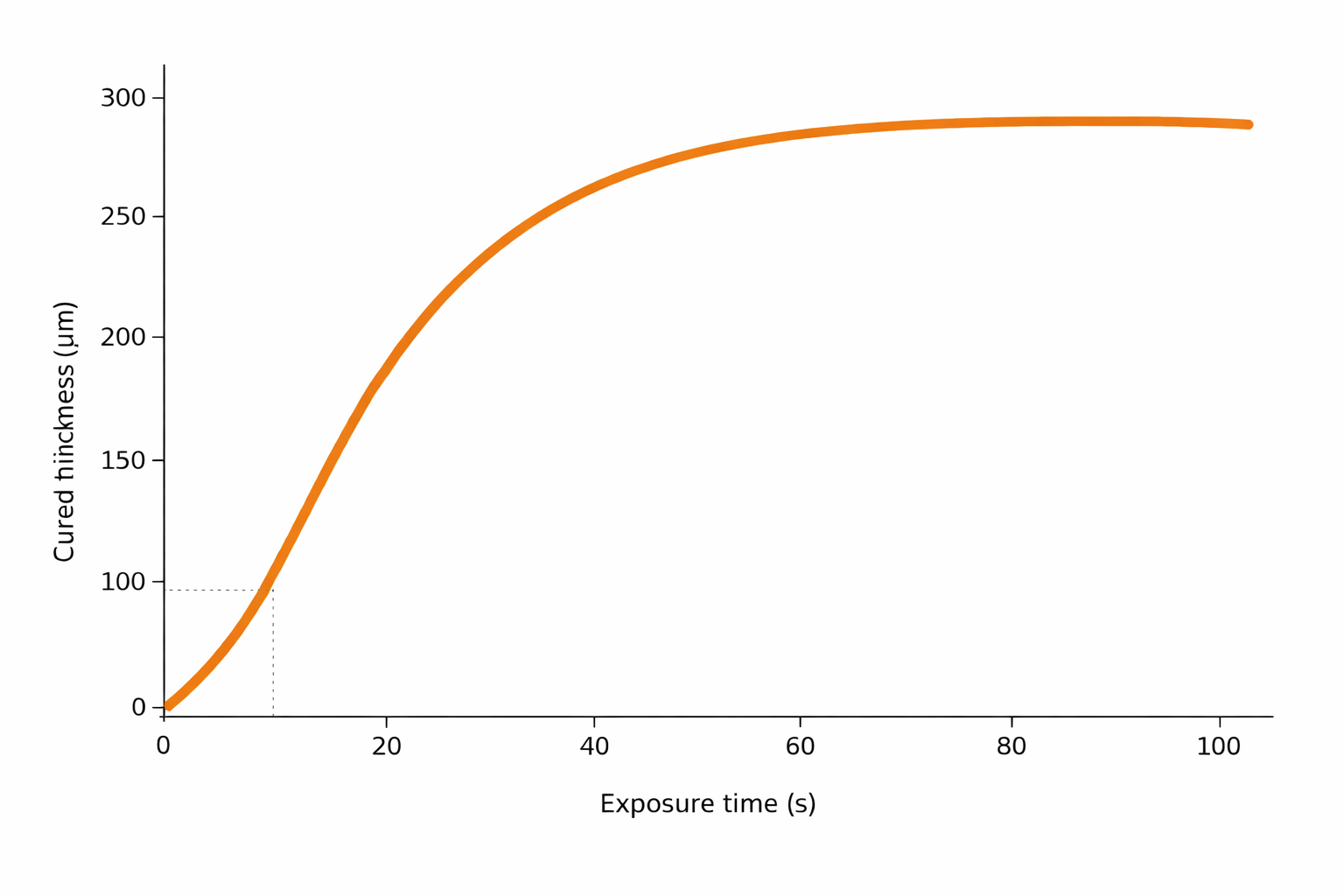

The Curing Rate Table (CRT) is a quantitative fingerprint of how a specific 3D resin cures at a defined light power. It reports cured thickness (µm) at increasing exposure times (typically 5–100 s) at 405 nm.

5.2 How to obtain a CRT

- Order the CRT for each resin (measured at a light power matched to your printer): Curing Rate Table (CRT)

- Or measure it yourself following our Detailed IFU

For maximum accuracy, we recommend measuring your printer with the same light meter we use: Chitu Systems Digital UV Light Meter.

6) Fast calibration protocol (recommended)

- Measure your printer’s light power at the centre of the vat (mW/cm²).

- Share the measured value with us.

- We generate the CRT at the same light power (light-power matching).

- Select your target z-layer thickness (e.g., 50 µm or 100 µm).

- Select supports, density, tip size, and exposure time accordingly.

7) How to choose the optimum exposure time (practical rule)

From the CRT, select the exposure time that cures a thickness equal to or slightly greater than your chosen z-layer thickness.

- Start with the exposure corresponding to ~1.2–1.5× the layer thickness.

- If prints are under-cured (soft/weak, layer separation) → increase exposure.

- If prints are over-cured (brittle, excessive adhesion to FEP) → decrease exposure.

8) Quick validation prints

8.1 Calibration step 1: Print 3DTest1 (flat coin, no supports)

This fast test evaluates:

- General printability

- XY resolution

- Resin curing behaviour

The coin includes concentric rings from 500 µm down to 2 µm. The smallest clearly resolved ring indicates the achievable XY resolution.

8.2 Calibration step 2: Print 3DTest2 (coin with supports)

This test evaluates:

- XYZ dimensional accuracy

- Support performance

- Z-axis accuracy after support removal

Z-accuracy example: if printed thickness = 2.1 mm and nominal = 2.0 mm → error = (2.1−2.0)/2.0 × 100 = 5%.

9) Interpreting failures (quick fixes)

- Coin detached from build plate: increase bottom exposure time and/or number of bottom layers.

-

Partial print failure:

- Soft/weak → under-cured → increase exposure.

- Brittle / sticks to FEP → over-cured → reduce exposure.

10) Basic tools for fast calibration

- Optional but recommended: UV light meter (~50 €)

11) Relationship to official Instructions for Use

This Fast IFU must always be used together with:

- Instructions for Use (IFU) & Printing Parameters for DLP & LCD printers

- any relevant printer-specific IFU,

- any application-specific IFU, where applicable.

In case of discrepancy, the official IFU always prevails.

12) Governing principle

This Fast IFU provides practical guidance only. Final material performance depends on formulation version, printer configuration, exposure strategy and post-processing workflow and must be validated by the user for the intended application.

13) Contact

For calibration support or resin selection, contact us at info@3dresyns.com.