3D-ADD CBA1 Bio Biocompatible Chemical Blowing Agent for foaming 3D prints

3D-ADD CBA1 Bio Biocompatible Chemical Blowing Agent paste has these features and benefits:

- universal blowing agent paste which can be added to thermoplastic SLA, DLP & LCD 3D resins before printing to produce after printing expanded cell sponges or foams upon heating

- supplied as a ready to use whitish paste

- biocompatible

- safe, non dangerous and non flammable as supplied and after heating

- stable, long shelflife (1 year guarantee, but in practice several years if kept at <70ºC )

- easy addition and dispersion in most compatible 3D resins with mild mixing

- hand mixing or rotary lab mixers can be used for mixing eg at 500 rpm for 10 minutes

- excellent stability without sedimentation during printing after mixing it with most 3D resins

- order also 3D-ADD ASC1, our anti sedimentation additive, for maximum custom control of stability (non-settling)

- doest not affect the original mechanical properties of the 3D resins

- causes whitening in clear 3D resins

- causes minor whitening effect on the color of the chosen colored 3D resin

- addition dosages of 10-20% by weight on resin solids are recommended for expanding the resin upon heating

- releases non-toxic inert blowing gas upon heating at 140-180ºC

It is supplied as a kit, which contains the product, one graduated beaker and one empty 250 mL black bottle to measure, mix, keep and protect the 3D resins from daylight. Please do not expose any 3D resins to natural or room light to prevent their curing.

🔹 Technical Bulletin – Advanced Use of 3D-ADD CBA1 Bio

Thermally Activated Foaming for 3D Printing Resins

3D-ADD CBA1 Bio is a biocompatible, paste-based chemical blowing agent designed to enable post-print foaming and internal porosity in selected 3D printing resins through a controlled thermal activation process.

This bulletin provides application guidelines, processing parameters, and material compatibility information for users exploring lightweight, foam-like structures in resin-based additive manufacturing.

How 3D-ADD CBA1 Bio Works

3D-ADD CBA1 Bio remains inactive during printing and UV curing, ensuring full print stability and workflow compatibility.

During post-processing thermal treatment, the additive activates within a defined temperature window, generating an internal expansion effect once the resin matrix has sufficiently softened. This results in foam-like or porous internal structures and reduced part density.

Activation occurs exclusively during post-processing and does not require any modification to printing hardware.

Recommended Processing Workflow

1. Resin Preparation

- Recommended loading: 10–20 wt%

- Paste format enables easy dosing and homogeneous dispersion

- Mix gently to avoid air entrapment

2. 3D Printing

- Compatible with SLA, DLP, and LCD technologies

- Moderate viscosity increase may occur

- Minor reduction in optical clarity is expected

3. UV Post-Curing

- Standard post-curing recommended

- Avoid excessive over-curing to preserve thermal responsiveness

4. Thermal Foaming (Post-Processing)

- Heating method: convection oven, thermal chamber, or controlled hot plate

- Heating rate: 1–3 °C/min

- Activation temperature: 140–160-180 °C

- Typical dwell time: 10–20 minutes, depending on geometry and thickness

Resin Compatibility & Expected Performance

Flexible resins – Shore A 20–50 (Recommended)

- Resin softens sufficiently during activation

- Density reduction: 10–30%

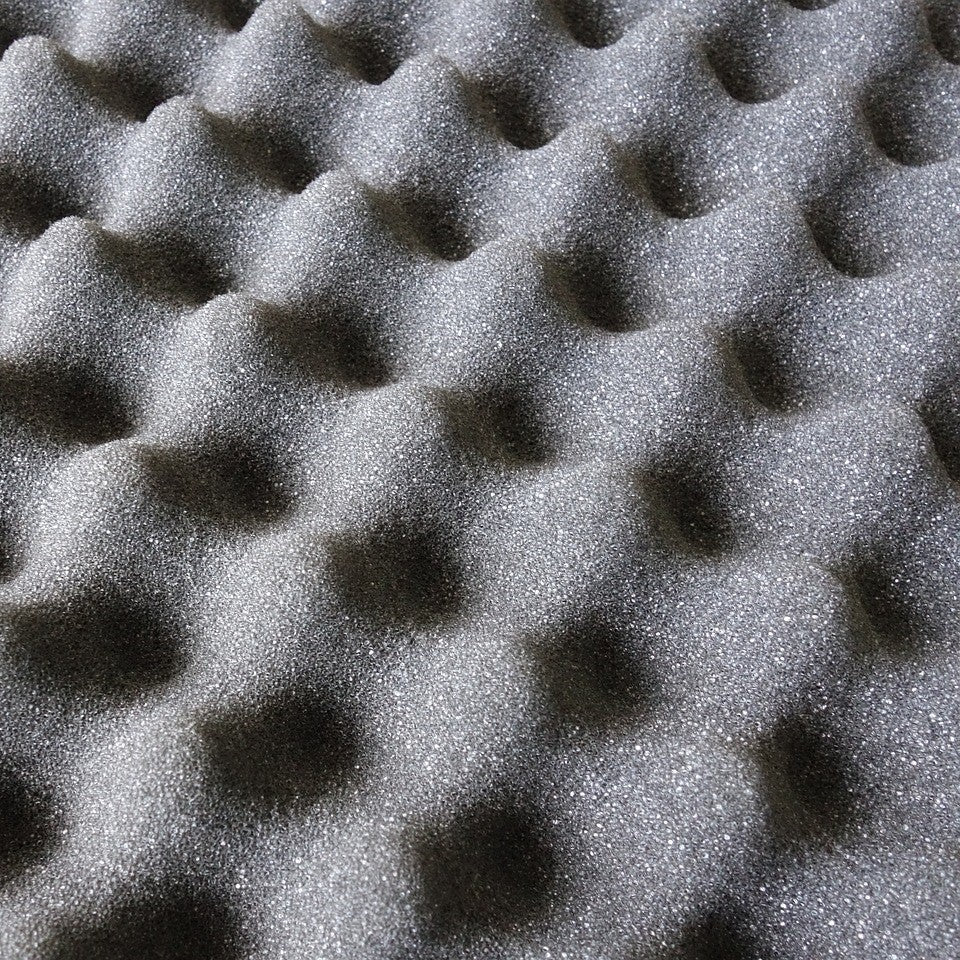

- Internal structure: soft, open, foam-like

- Suitable for soft-touch components, cushioning concepts, and lightweight flexible prototypes

Semi-flexible resins – Shore A 60–90

- Reduced matrix compliance

- Expansion becomes localized and less uniform

- Partial porosity achievable

Semi-rigid resins – Shore D 30–60

- Limited deformation during activation

- Expansion appears mainly as isolated internal voids

Rigid resins – Shore D >60

- No effective expansion response

- Not recommended

Typical Outcomes

- Expansion ratio: up to ~1.3×

- Density reduction: 5–30%

- Cell morphology: organic, open, irregular

- Mechanical response: softer, more compliant

- Visual effect: sponge-like internal texture

Design & Application Guidelines

Recommended for

- Lightweight concept models

- Experimental material development

- Soft-touch and ergonomic parts

- Non-structural applications

Not recommended for

- Load-bearing components

- High-resolution surface detailing

- Tight dimensional tolerances

3Dresyns Technical Positioning

3D-ADD CBA1 Bio is positioned as an exploratory foaming additive for users seeking accessible post-print expansion and material innovation in resin-based additive manufacturing.

For applications demanding finer cell control, higher repeatability, or industrial-grade foam performance, 3dresyns offers advanced expansion technologies through its customized 3D resin design portfolio.

Choose options