IFU for SLS printing

3Dresyns SLS powders for Selective Laser Sintering printing, nylon 11 white, nylon 12 white, and ThemoPlastic Elastomer TPE black, have been designed to exhibit similar printing settings than the existing commercial products with the same composition and color.

Our SLS powders (nylon 11, nylon 12, and TPE (PEBA type)) have the same printing parameters as equivalent commercial products to facilitate product replacement without any calibration problems.

These fast and accurate Instructions for Use "IFU" can be used for printing 3Dresyns SLS powders with most SLS printers:

SLS 3D printing settings adjustment (calibration)

The main variables which can be adjusted are the bed temperature, laser power, laser scan speed, and the optional usage of laser absorbing additives:

Bed temperature adjustment

- The adjustment of the bed temperature requires the previous determination of the sintering window which is the temperature window in which the sintering and binding of the powder occur. Excessive bed temperature over melts the powder, whilst too low bed temperatures exhibit poor sintering/ binding of powders, poor mechanical properties, or print failure, caused by poor coalescence

Laser power and/or scan speed adjustment

- Powder sintering occurs by the heat absorbed by the powder upon exposure to the laser at certain power and scan speed

- Low power lasers need longer scan speed to sinter powders

- By increasing the laser power and/or the scan speed at certain bed temperature the printing settings can be optimised for each type of powder or powder blend

- Delamination and poor cohesion of prints of prints can occur with too low laser power and/or too high scan speed

- Dimensional accuracy loss and brittleness can occur with too high laser power and/or too low scan speed

Adjustment by adding laser absorbing additives

- The addition of laser absorbing additives, such as carbon black powder at small dosage eg at 1-5%, can be used with slow printing powders (powders with low laser absorption and heat emission)

Optimisation of printing settings is straightforward with extensively used powders, such as nylon, but it is particularly required when using exotic powders, your own powder blends, and with Cold Metal, Ceramic, Polymer & Exotic Powders Fusion. Read our IFU for SLS Cold Metal, Ceramic, Polymer & Exotic Powders Fusion

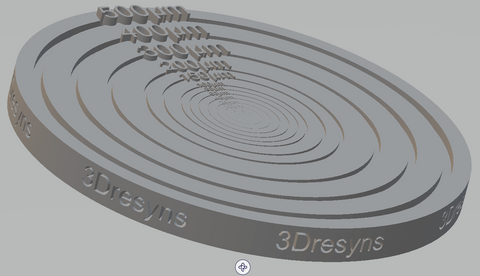

Calibration test

- Calibrate 3Dresyns SLS powder in your SLS printer by printing 3Dtest1, 3Dresyns flat coin, for fast optimisation of the resolution and printing settings

- Each SLS printer will require different printing settings for each powder depending on their composition, molecular structure, and physicochemical characteristics

- Slice the 3Dtest1 file into layers with the standard printing settings of your closest equivalent SLS powder

- Send the instructions (sliced STL file) to the printer

Adjustment and calibration of SLS printing settings

- Printer setup varies and depends on each SLS printer system

- Follow the manual and IFU for the equivalent SLS powder material of your SLS printer manufacturer before printing

Post processing

- After printing wait until the build chamber cools down before post-processing to prevent warping of prints.

- Remove the prints from the build chamber

- Clean prints: remove manually excess powder. This process is typically completed manually and with compressed air

- Smooth grainy prints if needed with Cleaning Fluid WS1 for cleaning and smoothing prints

- Recycle the excess unfused powder by filtration and re-use it by mixing it with fresh SLS powder for next print jobs