Introduction to 3D Printing and Additive Manufacturing

![]()

3Dresyns Statement

“3D printing enables both direct and indirect additive manufacturing of an endless number of high-performance and biocompatible materials—covering a wide range of physical, chemical and mechanical properties—with precise dimensions and minimal investment. It is a key manufacturing revolution of the 21st century, empowering individuals and companies to become manufacturers of multifunctional 3D-printed materials.”

Gallery highlights

See what you can make with 3Dresyns

Pictures of real 3D printed Material systems

Videos of real 3D printed Material systems

Direct vs Indirect Additive Manufacturing

Want to manufacture plastic, ceramic, metal or exotic parts with 3D printing and rapid additive manufacturing? Below is a practical overview of the main pathways.

We focus mainly on SLA-based processes because they offer:

- Higher resolution, precision and dimensional accuracy than many other technologies (e.g., FDM)

- Low entry cost: many SLA/DLP/LCD printers range from ~€200 to €2,000+

- The widest material availability: explore our 3Dresyns collections and our printable exotic materials portfolio

Photoreactive 3D resin printing technologies

- Laser SLA: a laser scans and cures resin layer-by-layer

- DLP: projected light cures each layer

-

LCD: an LCD mask controls light transmission to cure each layer (LED source underneath)

- RGB LCD: “standard” LCD panels

- Monochrome LCD (MLCD): higher efficiency and speed

- Inkjet: resins are jetted hot and photocured layer-by-layer

- Other printing technologies

1) Direct AM (1 step)

Definition: Direct printing of parts using SLA, DLP, LCD, Inkjet or other technologies (including ceramic/metal 3D resins).

Benefits

- One-step process: print models, prototypes and functional parts directly

- No expensive tooling required

- Fast for short runs (low number of units)

- Ideal for frequently changing designs

- Low printer cost for SLA/DLP/LCD resin printing

- Very high mechanical performance can be achieved with our functional engineering 3D resins

Drawbacks

- Less cost-effective for long runs

- Longer production time for high unit volumes

- Many competitor resins show lower mechanical properties than injected engineering plastics (unless advanced materials like 3Dresyn Nylon-like or our best functional engineering grades are used)

- Many competitor resins are fragile (“eggshell” / “Christmas ball” effect)

- Each resin typically needs tuning per printer model—made easier with our fast & easy printing instructions

- Direct printing of highly loaded ceramics/metals and exotic powders has limitations compared to indirect routes:

- Debinding + sintering can be slower than CIM/MIM/PIM

- Ceramic/metal printers can be significantly more expensive (often €80k–€350k)

- Sintered properties can be lower (anisotropy, porosity, density)

- Formulation tuning is more challenging for direct ceramic/metal printing

Alternative direct route: SLS printing with non-photoreactive powder binders

- SLS: layers of polymer/metal powders are selectively sintered to form objects

- 3Dresyns developed universal bio-based, non-photoreactive powder binders for mixing with ceramic, metal, polymer or exotic powders/fibers: Powder binders for SLS printing of Ceramic, Metal & Polymer powders

- This can also be considered Direct AM (mold-free), although parts shrink and usually require post-processing (chemical/thermal debinding and sintering)

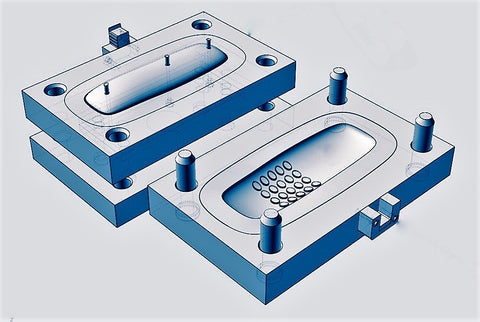

2) Indirect AM (2 steps)

Definition: Print molds (durable or sacrificial) using SLA/DLP/LCD/Inkjet, then inject/cast plastics, resins, ceramics, metals, polymers and exotic materials.

Types of injection molds

- Ultra-durable (CNC aluminium/steel): ideal for long runs of the same design

- Durable 3D printed molds: 3D printed molds for short & medium runs

-

Sacrificial molds: 3D printed sacrificial molds for complex intertwined geometries, removed by:

- Water: water-soluble molds

- Solvent: solvent-soluble molds

- Burn-out: castable

- Melt-out: heat-soluble “meltable” resins

- Break-out: easy-breakable cocoon molds

Types of indirect manufacturing

- Resin/plastic injection & casting: conventional casting resins at room temperature or injection & casting resins at >70–80ºC (gravity casting in the mold)

- Metal casting: molten metals cast into gypsum molds made from castable 3D resins or waxes

- High-temperature plastic injection: thermoplastics or high-viscosity injection resins (injection resins) injected hot under pressure into 3D printed molds

- Ceramic & metal feedstocks for CIM/MIM using dedicated binders injected hot under pressure into 3D printed molds

- Powder feedstocks for PIM and exotic materials, also injected hot under pressure into 3D printed molds

Injection systems

For indirect manufacturing, injection equipment ranges from low-cost manual tools to industrial systems:

- Manual micro-syringes (<€50) for micro-injections: borosilicate glass syringes or metal syringes

- Manual dental injection units (~€300–€3,000): manual injection machines

- Automatic injection machines (~€3,000–€7,000+)

In these systems, solid or viscous feedstocks are heated and injected under pressure into molds. Ceramic and metal parts typically require debinding and high-temperature sintering to obtain fully sintered parts.

Why indirect manufacturing?

Injecting PIM feedstocks (ceramic, metal, polymer such as polyimide, and exotic materials) into 3D printed durable or sacrificial molds offers major advantages compared to direct printing of highly loaded photopolymer resins.

Benefits

- Faster and more cost-effective for medium & long runs

- Enables production with injected engineering plastics (e.g. polyamide/nylon), not typically printable by resin systems— unless using 3Dresyn Nylon-like and our best functional engineering grades

- Ideal for cost-effective manufacturing of pure ceramics, metals, sinterable polymers and exotic materials

- No tuning for every “final material”: you tune the mold resin once (durable or sacrificial) and reuse it (durable / sacrificial)

- Often improved debinding/sintering workflow versus direct highly loaded printing

- Affordable printers (<€1,000) can be used to print the molds

- Better sintered material properties: higher isotropy and density, lower porosity

Our Mission

“Any color, any material, any process, any finishing, any end-use application—on any SLA, DLP, LCD and Inkjet printer.”

3Dresyns offers the widest range of safe functional SLA, DLP, LCD and Inkjet resins for reliable printing of functional and biocompatible materials.

How to buy: Shop online in just a few clicks and access one of the widest resin portfolios in the market to achieve the finish and quality your application requires.

“The aim of 3Dresyns is to provide the best stereolithography and inkjet resins and solve unmet market needs for any material, process and application.”

“3Dresyns is committed to innovation and the development of safe and biocompatible 3Dresyns using safe synthetic and bio-based raw materials from renewable sources.”

Discover more about 3D Printing & Additive Manufacturing

- In depth 3D Printing and Additive Manufacturing

- 3D Printing Technology: What Materials Can We 3D Print So Far!

- About nano and micro 3D printing

- Indirect Additive Manufacturing: Pros & Cons

- Direct Additive Manufacturing of 3D printed products

- Indirect Additive Manufacturing of 3D printed products

- Direct and Indirect Additive Manufacturing

- Ceramics and Metals: Direct or Indirect AM? Pros & Cons