Made to order 3Dresyns for most SLA, DLP & LCD printers

3Dresyns are made to order and compatible with most photopolymer SLA, DLP and LCD/MSLA 3D printers. Each resin is supplied ready to print and tuned to your printer’s optical specifications so you can achieve consistent printability, dimensional accuracy and high mechanical performance.

How do we ensure compatibility across different printers?

Printer performance depends on optical variables such as wavelength, real irradiance, and power distribution across the vat. We adapt (fine-tune) our resin systems to the relevant specifications of most commercial printers, so the resin you receive is aligned with your setup from day one.

Features & benefits of our SLA, DLP & LCD 3Dresyns

- Made to order for your printer model specifications.

- Broad optical compatibility: printers using lasers, DLP projectors, and multicolor/monochrome LCD panels.

- Typical wavelength coverage: 150–420 nm (including 355, 365, 385 and 405 nm), including daylight printers (e.g., Photocentric), and up to 500 nm when using our visible / biocompatible Fine Tuner additives.

- Scales from micro to macro: compatible with ultra-high-resolution micro-scale systems and large-format printers.

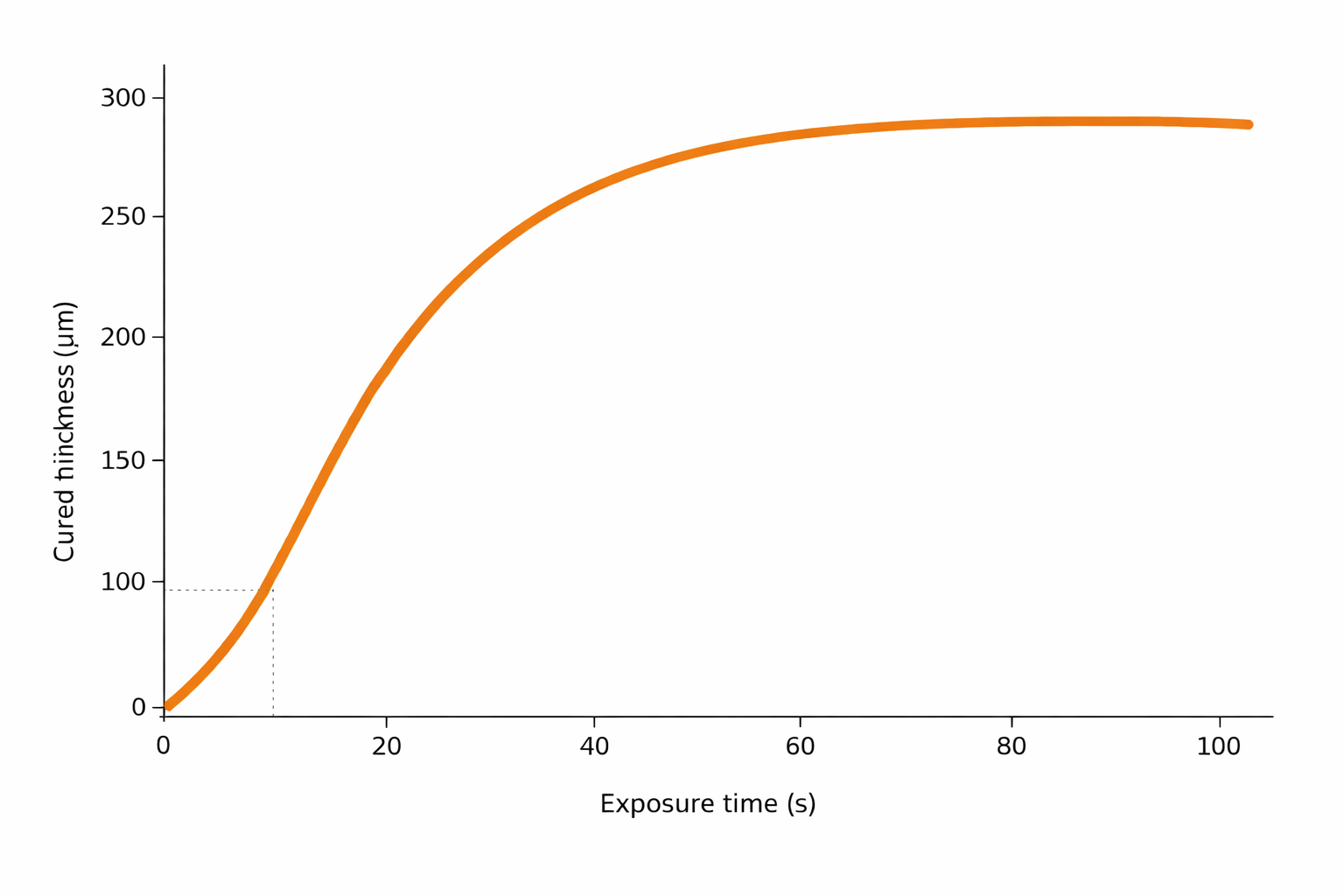

- Optional Curing Rate Table (CRT): thickness vs exposure time data measured at 405 nm at a light power similar to your printer (5, 10, 15, 20, 25, 50, 75 and 100 seconds). Order the CRT.

- Ideal for quickly identifying optimum exposure settings and applying a controlled calibration logic.

- Workflow coverage: works with top-down, bottom-up and CLIP-style workflows (where applicable to the printer technology).

- Designed and tuned to your printer’s wavelength and real power.

- Examples of compatible SLA, DLP & LCD 3D printers

- Order-size discounts available.

Example: Formlabs compatibility

- 3D resins for Formlabs printers

- All our 3D resins are compatible with masked SLA systems such as Form 4.

- Many of our resins can be printed on Form 2 (open mode using Clear v2 settings) and Form 3 (Standard Clear or Grey settings), with or without a universal cartridge system.

- Compatibility of our uni- and multi-functional 3D resins

- 3Dresyns goals are your own goals

Black box printing vs clear box printing

If you want a simple “plug & play” experience (without specific technical or safety requirements), original printer-brand resins can be adequate for basic prototyping. However, they often become limiting as soon as you need higher performance, tighter tolerances, better repeatability, or safer materials.

If you print functional materials and need high mechanical performance, process constancy, and reproducible results, explore our multifunctional resin range and our 3D printing consulting services.

Learn why printing failures happen and how to fix the “black box” approach: Unlock the black box.

Fast calibration for speed vs accuracy

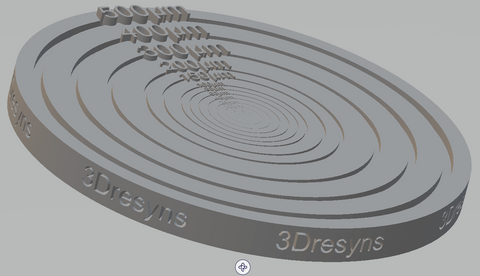

Our calibration files help you choose the right balance between printing speed and dimensional accuracy (example below: calibration coin reaching very high resolution).

Clear box calibration is simple: choose your target Z layer thickness, then select exposure times using a measurement-based logic.

By measuring cured thickness at a set of exposure times (e.g., 5, 10, 15, 20, 25, 50, 75 and 100 seconds), you obtain a fast “fingerprint” of your resin’s curing behavior on your printer. Use 1 mm glass slides or a piece of clear FEP film as the support for curing drops.

This fingerprint is essential because light power varies from printer to printer and decays naturally over time, which changes optimum exposure settings.

Optional: the Curing Rate Table (CRT) for each ordered resin (measured at 405 nm at a light power similar to your printer) is ideal for fast identification of optimum printing settings in SLA, DLP and LCD printers operating around 405 nm.

Do you need 3D printing consulting?

If you are fighting with your printer in a “black box” approach, need more control of the variables affecting performance and reproducibility, or you are choosing a new printer and want a professional setup from day one, consider our consulting and training services: 3D printing consulting.

Instructions For Use (IFU) & Printing Parameters

We provide free, detailed Instructions for Use (IFU) & Printing Parameters upon request after ordering, to help you identify the best settings for your printer.

- Calibration STL files (including a horizontally positioned coin – one of the most demanding orientations for Z-axis resolution) help confirm printability and determine XYZ precision before printing your own designs.

- The IFU provides a clear fingerprint of achievable printing speed and resolution for your selected resin on your printer.

- You choose the final balance of speed vs resolution by following simple calibration steps.

Basic tools needed for calibration

- Digital caliper

- Microscope glass slides or a small piece of FEP film

Need help confirming compatibility?

Share your printer model, technology (SLA/DLP/LCD), wavelength (if known), target layer thickness, application and intended post-processing workflow.

After placing your order, request our IFU & Printing Parameters by email: info@3Dresyns.com

For ordering and lead times, see: Ordering, prices & lead times.