Volumetric Additive Manufacturing (VAM) enables rapid fabrication of three-dimensional objects by curing a photoreactive material throughout a volume, rather than layer-by-layer. This approach can significantly reduce build times and can unlock new geometries and process windows for additive manufacturing.

What is VAM?

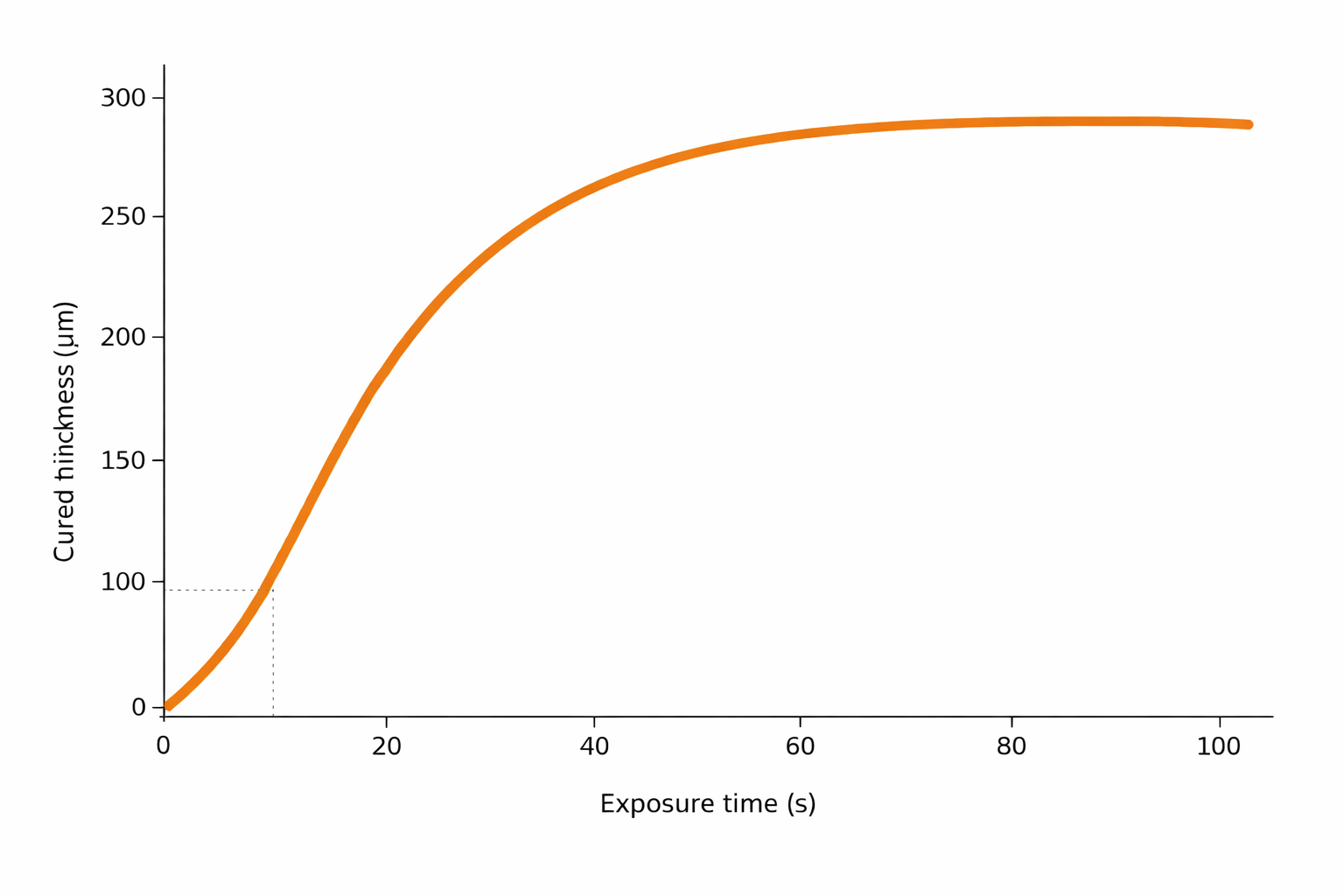

In volumetric printing, a vat of resin is exposed to time-varying light patterns that deliver a controlled dose distribution inside the material. Where the accumulated dose exceeds the polymerization threshold, the resin solidifies, forming a 3D part in a single volumetric step.

Dynamically evolving light fields

Dynamically evolving light patterns can be generated by projecting sequences of images while rotating the resin container, by using computed tomographic reconstruction approaches, or by other optical strategies that shape the 3D dose field in time. In all cases, resin photoreactivity, inhibition, diffusion, scattering, and optical attenuation directly determine achievable resolution and part fidelity.

Material requirements for volumetric printing

VAM places specific requirements on photopolymer chemistry and formulation. Key parameters typically include:

- Well-controlled polymerization threshold and dose accumulation behavior

- Low optical scattering and suitable absorption at the printing wavelength

- Balanced radical kinetics and inhibition control to prevent unintended background curing

- Viscosity and diffusion control to maintain spatial fidelity during exposure

- Post-processing routes compatible with the target application and safety requirements

3Dresyns development approach

3Dresyns develops photoreactive resin systems and tuning additives to support volumetric printing concepts, including dynamically evolving light-pattern strategies. Our work targets predictable cure behavior, process stability, and robust mechanical and chemical performance of printed parts.

Discover our technology scope: Continuous Additive Manufacturing and continuous and semi-continuous variable-composition printing .

Applications

VAM can be relevant for rapid prototyping and end-use production where cycle time and geometry benefit from non-layered curing, including advanced tooling, microfluidics, functional parts, and photonic components, depending on achievable resolution and validated material performance.

Custom development

3Dresyns can custom-design resin systems and workflows to match specific volumetric printing architectures, wavelengths, optical paths, and performance targets.

Contact: info@3dresyns.com