Our portfolio of SLA, DLP & LCD 3D resins for making Injection Molds (IM) includes durable and sacrificial mold materials with different heat deflection temperatures and rigidities, enabling injection of a broad range of injected materials.

Portfolio

Injected materials and feedstocks

- Silicones

- Waxes

- Low, medium, and high injection (processing and/or curing) temperatures up to 200ºC or higher, for injection of traditional materials such as:

- Plastics such as our new casting or Plastic Injection 3Dresyns, which are light and/or heat curable biocompatible resins

- Polyurethanes for making aligners with the benefit of reducing production costs (laser cutting is not required)

- Nylon (polyamide 12) for making partial flexible dentures

- PMMA for making rigid denture bases

- Etc

- Ceramic and metal feedstocks (Ceramic & Metal Injection Molding CIM and MIM) such as our Ceramic and Metal 3Dresyns slurries

Options

| Mold strategy | Recommended when |

|---|---|

| Non durable sacrificial molds 3D resins for printing sacrificial molds |

Complex shape, entangled or intertwined castings with the mold (soft or hard castings) where demolding requires sacrificing the mold. |

| Durable molds 3D resins for printing durable molds |

Simple shape molds and castings that are not too delicate, intricate, or entangled with the mold, where repeated use is required. |

Benefits of our durable and sacrificial 3D resins for printing injection molds

- Broad range of durable and sacrificial SLA, DLP & LCD 3D resins for making injection molds with a broad range of physical properties: from ultra high deflection temperature and rigidity to soft, flexible and elastic grades.

- Permit the injection and casting of any injected material, including thermoplastics (epoxies, polyurethanes, etc), thermosets (2 component resins, plastics, etc..), ceramic and metal feedstocks, with faster debinding than directly 3D printed ceramics, without any maximum wall thickness limitation, and with reduced risk of microcracking during debinding and sintering.

- More cost effective production of thermoplastic, thermoset, ceramic, and metal parts than traditional injection molding manufacturing and direct 3D printing of thermoplastics, thermosets, ceramics and metals.

- Printable with most commercial and professional SLA, DLP & LCD 3D printers.

- More versatile, faster, and more cost effective in short series production than aluminum CNC mold making.

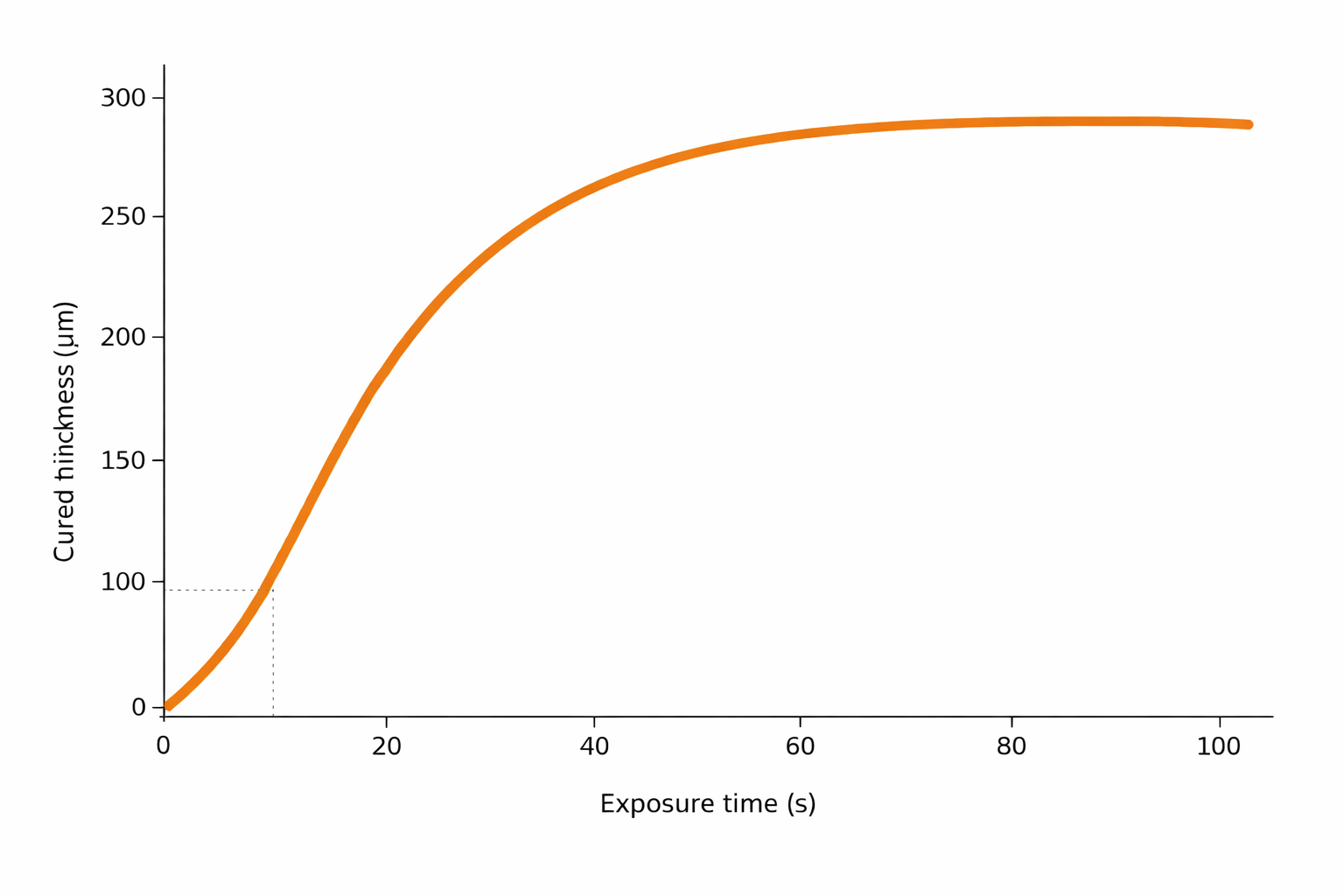

- High resolution up to 20 microns.

- Allow low cost, easy and fast mold design modifications.

Mold selection

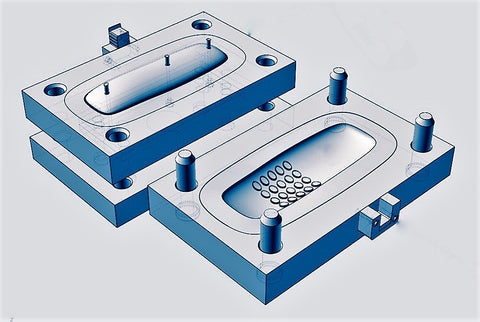

The key is how easily you can extract your castings from the 3D printed mold and the expected mold durability. Depending on the casting design, non durable “sacrificial” or durable molds will be needed.

Mold rigidity, hardness, and/or softness at certain injection (processing and/or curing) temperatures become important variables. The mold should be rigid enough to ensure dimensional stability of the casts at the selected injection and/or curing temperature.

For durable molds, avoid overly hard or rigid molds when demolding delicate simple-shaped parts, as insufficient flexibility can cause breakage. For soft materials injected at low pressures, relatively medium soft durable molds can combine dimensional stability and demolding flexibility.