3D bioprinting enables fabrication of biologically relevant 3D structures using bioinks engineered to support cell viability, controlled degradation, and application-specific mechanical performance. 3Dresyns develops bioinks and biocompatible photoreactive systems for research and translational workflows in tissue engineering and regenerative medicine.

What is a bioink?

A bioink is a printable formulation designed to be processed into a 3D construct while preserving biological function. Depending on the printing modality, bioinks can be based on hydrogels, reactive polymers, and composite systems that may include cells and bioactive components.

Key requirements for bioprinting materials

- High biocompatibility and low cytotoxicity after printing and post-processing

- Controlled rheology for print fidelity and shape retention

- Appropriate crosslinking kinetics for the selected printing technology

- Tunable mechanical performance (soft to resilient) to match the target tissue model

- Controlled swelling and degradation profiles

- Compatibility with sterilization and biomedical post-processing protocols

Bioinks for vat photopolymerization and light-assisted printing

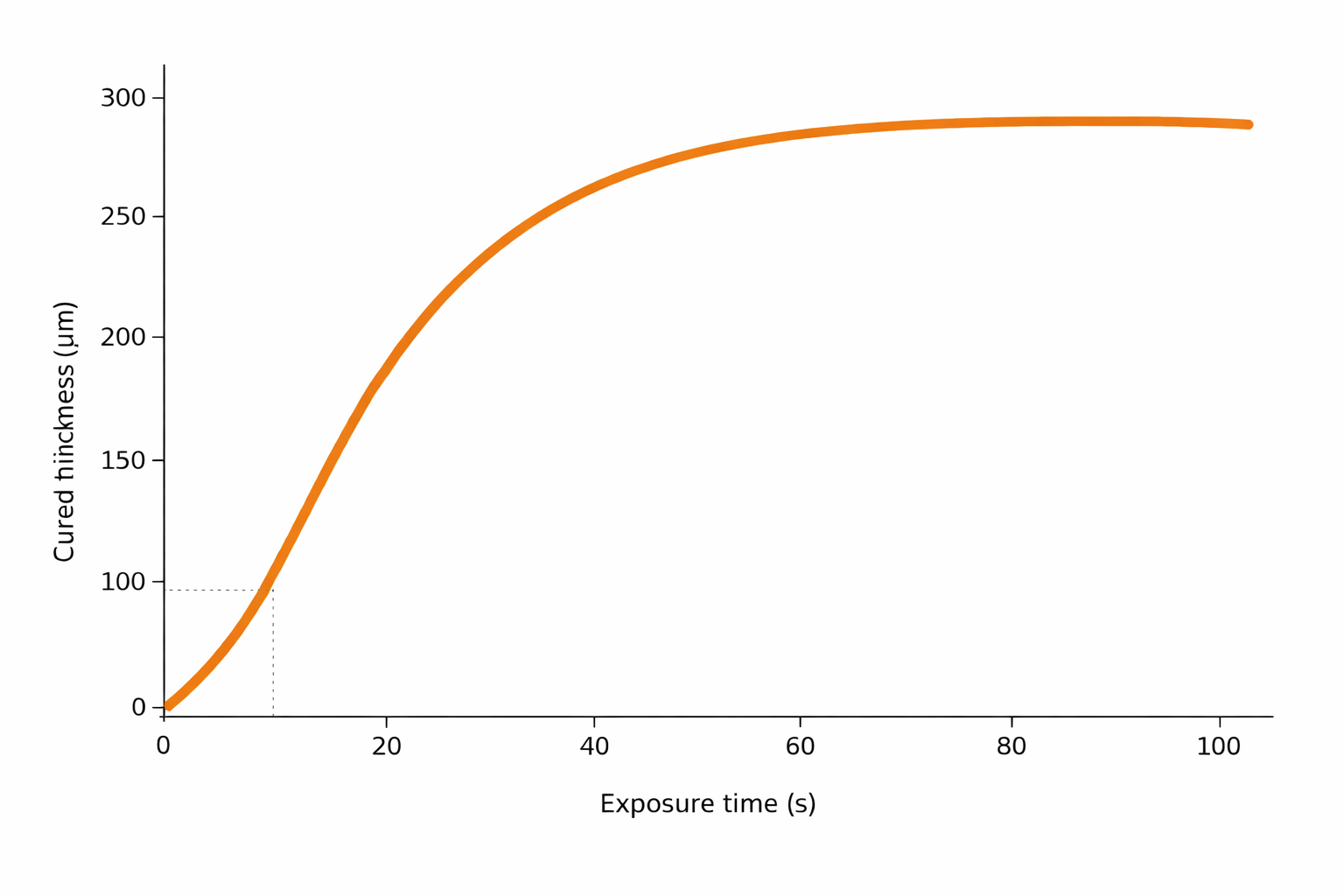

Light-assisted biofabrication (including SLA, DLP, and related modalities) requires photoreactive bioinks with predictable cure behavior and minimal residual extractables. These systems must be designed to achieve high conversion at low doses while maintaining suitable optical and rheological characteristics.

Learn more about process control and biocompatibility: implementation of biomedical protocols for maximum biocompatibility .

Typical bioprinting applications

- Cell scaffolds for tissue engineering

- In vitro tissue models and organ-on-chip systems

- Regenerative medicine research

- Drug screening and disease modeling

- Bioactive and degradable 3D constructs

3Dresyns bioinks and biocompatible resin families

3Dresyns provides biocompatible resin and hydrogel families, as well as custom development, to support bioprinting workflows from early research to application-driven prototyping.

Custom development

3Dresyns can custom-design bioinks and photoreactive systems for specific printers, wavelengths, rheology targets, and biomedical requirements, including protocols for cleaning, post-curing, and sterilization.

Contact: info@3dresyns.com