About nano and micro 3D printing and Additive Manufacturing

Nano and Micro 3D Printing describe additive manufacturing processes operating across different length scales, from nano and sub-micron to several hundred micrometre features of functional parts. Each scale addresses distinct technical challenges and enables specific applications, while sharing the same core principle: controlled, layer-by-layer material deposition or polymerization.

Nano 3D Printing

Nano 3D printing operates at sub-micron resolution, often below one micrometre. This scale enables the creation of structures that interact at the molecular, cellular or photonic level. Nano additive manufacturing is typically achieved using highly controlled photopolymerization techniques, such as two-photon polymerization.

Applications include nanodevices, photonic and optical components, biomedical research tools, advanced metamaterials and high-precision micro- and nano-architectures.

Micro 3D Printing

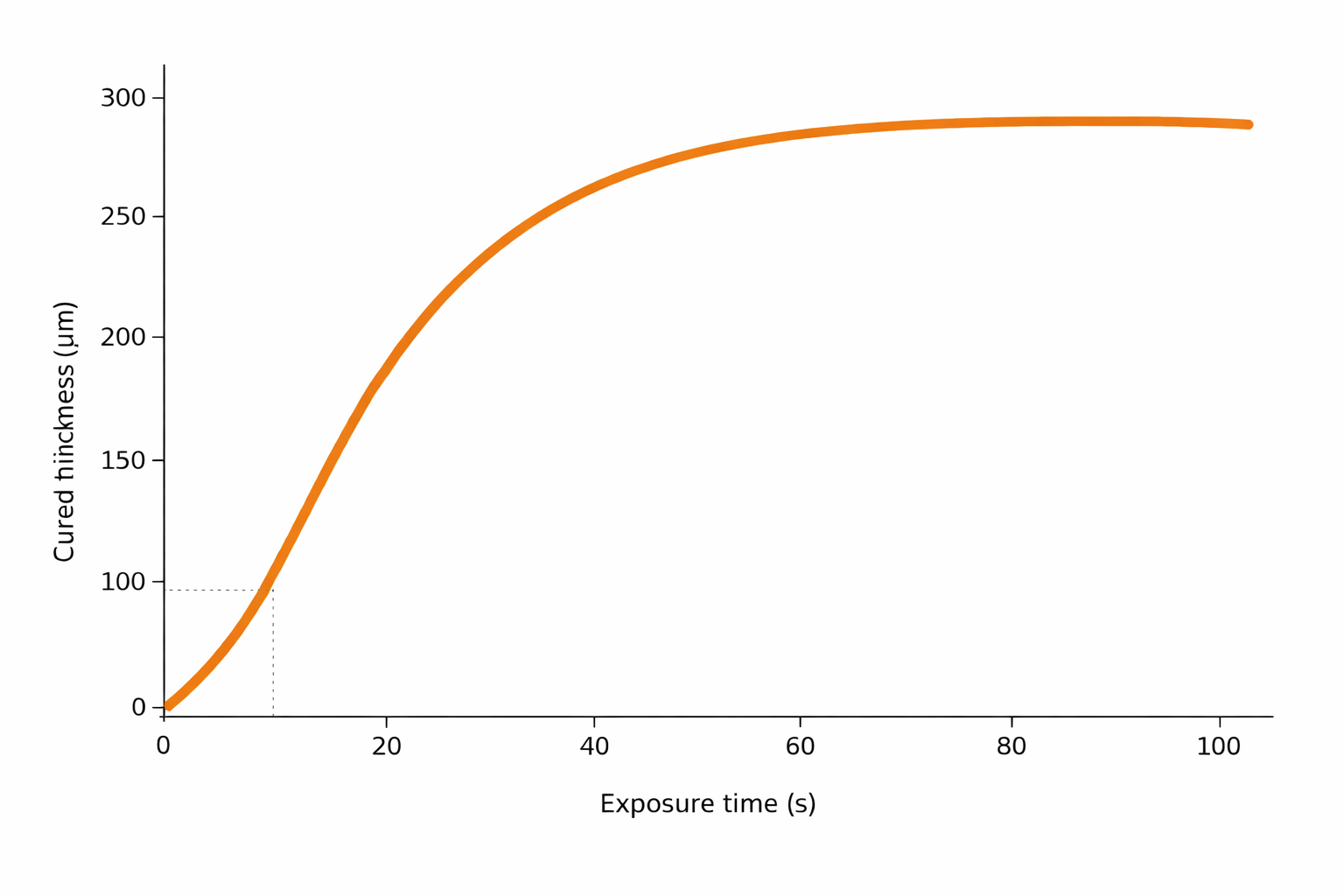

Micro 3D printing focuses on feature sizes typically between a few micrometres and several hundred micrometres. At this scale, resolution, precision and dimensional accuracy become dominant factors. Micro additive manufacturing enables the fabrication of complex geometries that are difficult or impossible to achieve using conventional micromachining.

Typical applications include microfluidic devices, sensors, micro-optics, medical and dental components, and functional microstructures where tight tolerances and fine details are required.

Macro 3D Printing

Macro 3D printing refers to additive manufacturing of parts ranging from millimetres to metres in size. This scale is commonly used for prototyping, tooling, fixtures and functional end-use components. Key advantages include geometric freedom, internal channels, lattice structures and reduced material waste compared to subtractive manufacturing.

Macro-scale additive manufacturing is widely applied in industrial production, engineering, aerospace, automotive, construction and consumer products, where mechanical performance, dimensional stability and repeatability are critical.

Why Scale Matters in Additive Manufacturing

The scale at which a part is printed directly influences achievable resolution, surface quality, mechanical behaviour and functional performance. Macro, micro and nano additive manufacturing are not competing technologies, but complementary tools that address different design and application requirements.

Modern additive manufacturing workflows increasingly combine multiple scales, enabling hierarchical and multiscale structures that integrate nano- and micro-features into macro-scale components.

Technologies Across Scales

Additive manufacturing technologies span a broad range of processes, including vat photopolymerization (SLA, DLP, LCD) for macro and micro parts, two-photon polymerization for nano and micro fabrication, inkjet-based systems, and powder-based processes for large or functional components.

Selecting the appropriate technology requires balancing resolution, material properties, throughput and post-processing constraints.

Relevance for 3Dresyns

3Dresyns develops and supplies material systems, additives and technical support for additive manufacturing across nano, micro and macro scales. Our approach recognises that materials are process-dependent systems, and that optimal performance is achieved by matching resin chemistry, printing technology and processing parameters to the targeted scale and application.

Understanding additive manufacturing across scales is essential for selecting the right technology, material and workflow, and for achieving reliable, reproducible and functional results.

Related documentation

- Two-Photon Polymerization (2PP) 3Dresyns® for nano- & micro-fabrication

- Instructions for Use (IFU) for 2PP Printers

- Advanced photopolymer manufacturing (2PP, NIL photoresists, VAM)

- Technologies (nano-to-macro additive manufacturing)

- Materials (nano-to-micro fabrication workflows)

- Microfluidic 3Dresyns® (example nano/micro application)

- Multivariable photopolymer resin systems

- Material and Documentation Finder