Recommendations for printing aligners

Printing aligners using photopolymer additive manufacturing requires careful control of material selection, printing parameters and post-processing workflows. Aligner performance is not determined by the liquid resin alone, but by the complete interaction between material system, printer technology and processing conditions.

The following recommendations are provided within a system-based and process-aware framework to support reliable and reproducible aligner printing workflows.

Material system selection

Aligner printing typically relies on biocompatible or application-specific photopolymer systems designed to support flexibility, dimensional accuracy and surface quality when processed according to qualified workflows.

Different resin systems and versions may be available to balance properties such as elasticity, strength, clarity and processability depending on the intended aligner design and use case.

Printing parameters and orientation

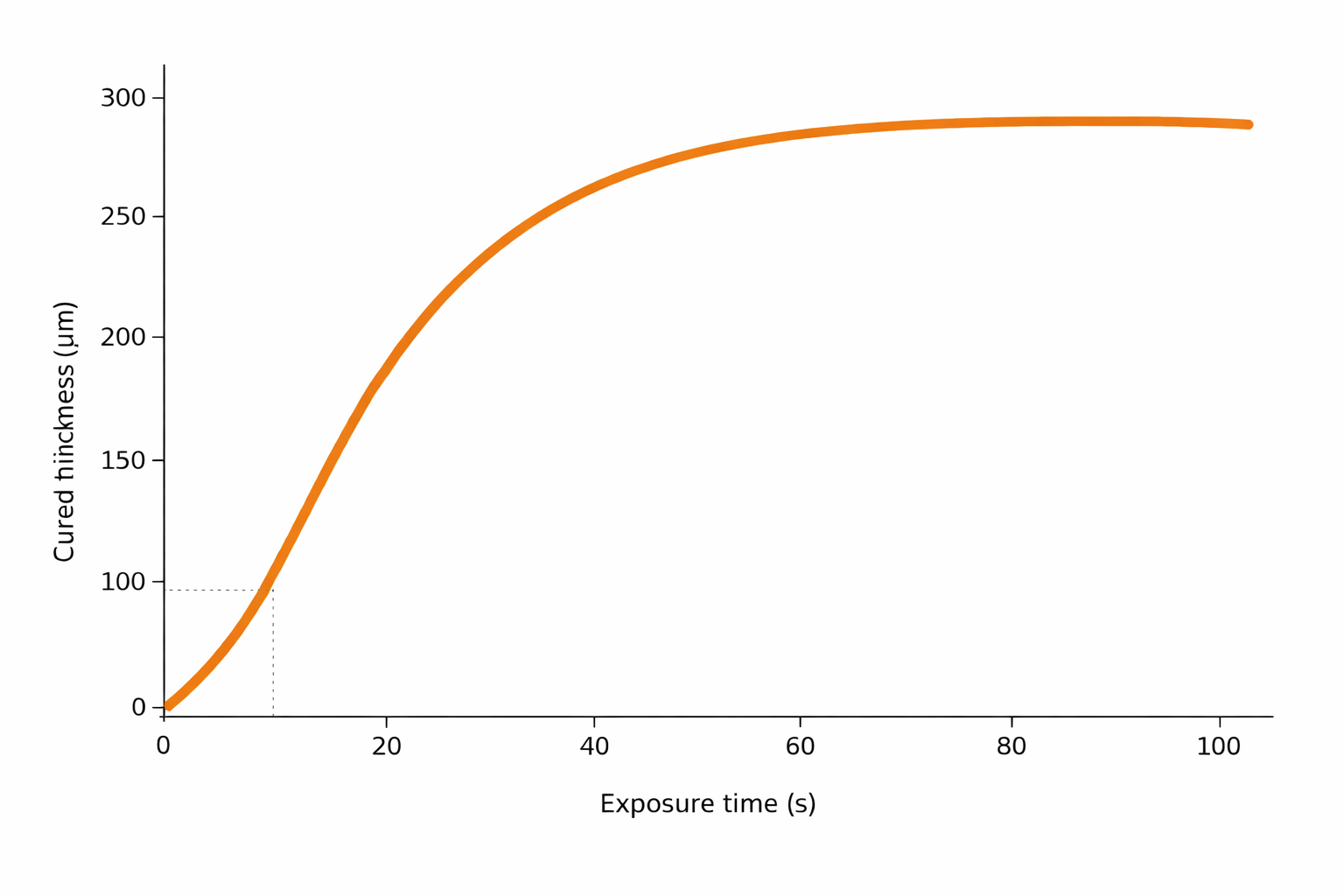

Printing parameters such as layer thickness, exposure strategy and build orientation have a significant impact on surface quality, dimensional accuracy and mechanical behavior of printed aligners.

Optimizing orientation and exposure helps reduce internal stresses, improve surface finish and ensure consistent thickness across the printed part.

Washing and post-curing procedures

Post-processing is a critical step in aligner manufacturing. Proper washing removes residual uncured material, while controlled post-curing ensures adequate polymerization and stabilization of material properties.

Incomplete or non-qualified post-processing may negatively affect flexibility, surface chemistry and biocompatibility outcomes.

Dimensional accuracy and fit

Achieving accurate fit requires consistency across the entire workflow, from digital design to printing and post-processing. Variations in printer calibration, material handling or post-curing conditions may lead to dimensional deviations that affect aligner performance.

Validation of the complete workflow is therefore essential before clinical or functional use.

Typical performance and workflow dependence

Reported material properties and aligner performance correspond to typical outcomes obtained under reference configurations and qualified workflows. Actual results may vary depending on printer technology, parameter selection and post-processing practices.

Aligner printing should be approached as a controlled system rather than as a single-step material selection exercise.

Governing principle

Aligner performance results from the combined selection of material system, version and qualified workflow. Mechanical behavior, fit and biocompatibility are typical responses obtained under reference configurations and are not intrinsic properties of the liquid resin alone.

This principle supports realistic expectations and responsible implementation of photopolymer 3D printing for aligner applications.