General Instructions for Use "IFU" for DLP & LCD printers

Standard settings for printing 3D resins with DLP & LCD printers:

- Z layer or slice height or thickness is typically between 50-100 microns (0.05-0.1 mm). Lower or higher are also printable for most 3D resins

- Cure or Exposure or z layer or slice or thickness times are typically between 1-10 seconds for the fastest resins and 10-20 seconds for the slowest resins

- Depending on the power of your printer, the optimum exposure times will increase or decrease. Follow our detailed Instructions for Use. Measure and fill up the data, cure thickness vs exposure time, in the curing rate table for your specific printer specifications. Alternatively, order online the curing the table for your ordered 3D resins measured with similar light power specifications with this light meter*

- Typically 3 initial, also known as adhesion, or bottom, or base, layer, or slice, or cure bottom count exposures of 80-100 seconds are enough for having very good adhesion on the build platform for most 3D resins

- Z lift & retract speed: low, medium, or high value of the scale (non-critical for most 3D resins)

- Light off delay/off time/wait before & after print: 0.1-0.5 seconds (non-critical for most 3D resins)

- Z Lift after print distance: 5-10 mm (non-critical for most 3D resins)

- Printing temperature: before printing warm viscous 3D resins, protecting them from room light to prevent their light curing, to around 30-35ºC to reduce their viscosity and adhesion to the resin tank

- Low viscosity resins do not require any warming

Taking into account the broad range of printer specifications (light power variability) of different printer models of even the same printer technology the optimisation of the printing settings, such as light exposure times, are required for each resin and printer unit because all printers have different light power across the vat available for curing and printing 3D resins. Additionally, the light power also decays over cumulative operating time or working hours. As example, the following graph shows a typical light output decay vs cumulative operating time of standard multicolour RGB LCD panels, monochrome LCD panels, digital lamp projectors and LED projectors, all typically used in SLA, DLP & LCD 3D printers.

For more info read:

- Power difference of DLP, LCD & MLCD printers and its consequences

- Do you want to go in depth? Let´s unlock the black box!

- Detailed Instructions for Use IFU for DLP & LCD printers

- Fast and accurate Instructions for Use "IFU" for DLP & LCD printers

Calibration of 3D resins in 3D printers

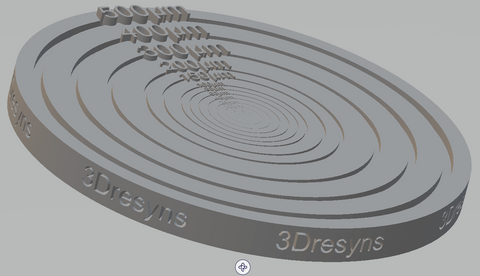

Our free supplied calibration files will help you choose the right balance of printing speed, resolution, precision, and dimensional accuray of your prints (see 3Dresyns calibration file of the coin below with resolution up to to 2 microns).

3Dresyns Instructions for Use IFU are practical, scientific, intuitive, fast, and easy to follow. There is no need to understand any complex concepts, theories, and equations as shown in detailed in Fundamentals of Stereolithography by 3Dresyns

Printing of most 3D resins is easy with our calibration instructions, which show you to choose the right exposure times and printing settings for your chosen z layer thickness, as shown in this video:

Basic simple scientific methodology for non-scientists

Instructions For Use IFU*

- Our calibration stl files (including the horizontally positioned coin shown above: most critical or difficult orientation for getting high z axis accuracy) are available for confirmation of printability, and for determining the xyz printing resolution, precision, and dimensional accuracy of the chosen printing settings in your existing printer, before printing your own designs

- Our IFU will provide you a full fingerprint of the achievable printing speed, resolution, precision, and dimensional accuracy of your chosen 3D resin with your printer specifications

- The optimum printing settings for your chosen balance of printing speed, resolution, precision, and dimensional accuracy will be chosen by you, following our detailed IFU, with just some basic calibration steps

- Our IFU do not require the use of complex working curves, nor mathematical correlation formulae of several variables such as:

- Cd = Cure Depth (μm or mm) (cured layer thickness), Dp = Depth of penetration (mm), Ec = Critical Energy (J/mm2), E = Energy dosage per area or light irradiation dose (mJ/cm2), variables which are included in the working curve equation: Cd = Dp • In(E/Ec)

- Our IFU are intuitive, fast & easy, and do not need the understanding of any complex concepts and equations, nevertheless technical 3D resins require technical printers

The difference between resolution, precision and dimensional accuracy

Resolution refers to the range of detail or minimum feature size which can be printed with detail. As shown on the surface of the coin the smallest feature size can be easily evaluated by reading the smallest concentric circle line on the surface of the printed coin, since each circle line has engraved its width and depth in decreasing order from 500 to 2 microns. On the other hand, precision refers to the capability to repeatedly print or "reproduce" the same dimensions of prints over and over again with certain variation. Keep in mind that extremely precise prints are not necessarily dimensionally accurate unless the tree spatial xyz dimensions of prints coincide with the three spatial xyz dimensions of the designed stl files which define the theoretical dimensions of prints as defined in the stl files.

Dimensional accuracy of 3D prints refers to how close the three spatial xyz dimensions of 3D prints are to the theoretical three spatial xyz dimensions of designed prints as defined in the stl file before printing. The stl file of 3Dresyns flat coin has 2 mm thickness (z axis) and 25 mm diameter (xy axis). The relative dimensional accuracy in the xyz axis can be easily measured by measuring the real diameter (xy axis) and thickness (z axis) of the horizontally positioned flat coin. For example, if the thickness of the printed coin is 2.1 mm. The difference between the theoretical and real value is 0.1 mm and the % difference is 0.1/2x100=5% which indicates the relative dimensional accuracy in the z axis. The same principle applies to the xy dimensional accuracy. If for example the diameter of the printed coin is 25.25 mm. The difference between the theoretical and real value is 0.25 mm and the % difference is 0.25/25x100=1% which indicates the relative dimensional accuracy in the xy axis.

Basic tools needed for calibration:

- Digital calliper

- Microscope glass slides or a small piece of FEP film

- supply for free upon request with your 3D resin orders

- Cost effective light meter of 50 Euro (optional)

Cleaning and postcuring of prints:

- For cleaning durable 3D resins use our ultra safe and biocompatible Cleaning Fluid Bio for colored prints, our non whitening Cleaning Fluid NW1 Bio for both clear and colored prints, and the ultra non whitening Cleaning Fluid UNW1 Bio for increased gloss, transparency, and biocompatibility, when used with the following Instructions for Use IFU:

- IFU for ultra gloss and transparency (without any haziness or whitish finishing of clear prints)

- IFU for colored 3D prints

- Instructions for Use IFU for biocompatible resins

- For cleaning water soluble sacrificial 3D resins use our Cleaning Fluid WS1 and Cleaning Fluid WS2 Bio with the following Instructions for Use IFU:

- For cleaning solvent soluble sacrificial 3D resins use our Solvent Solution SS1 Bio or Solvent Solution SS1F with the followings Instructions for Use IFU:

- Learn more about Sterilization of 3D printed resins for medical devices

Optional: Custom fine tuning of 3D resins for custom optimum balance of printing speed, resolution, precision and dimensional accuracy

Our SLA, DLP and LCD 3Dresyns can be fine tuned even further with our photoaccelerants (photocatalysts) and resolution increasers (resolutioners) for self-tuning their printing speed, resolution, precision, and dimensional accuracy with different printer types and printing settings, such as specific light power, exposure time per layer, z layer thickness and orientation of prints.

Free samples of our photoaccelerant (photocatalyst) Fine Tuner FT1 and of our resolutioner Fine Tuner LB1 Bio will be sent for self-tuning if necessary and upon request to provide maximum control and balance of printing speed, xyz resolution, precision, and dimensional accuracy.

Learn more about how to use our Fine Tuning additives for custom fine tuning of printing speed, resolution, precision, and dimensional accuracy

Black box printing vs clear box printing

If you are after a "plug & play" printing solution, without any specific technical and safety requirements, then consider purchasing the original non-functional "fragile" & "me too cheaper" 3D resins supplied with the printers. For certain time they will print certain basic 3D resins, but sooner or later will fail due to natural light power decay upon time of most printers.

On the other hand, if you need to print technical functional materials without variability, with high resolution, precision, dimensional accuracy, mechanical strength, and safety, and if you need specific functionality and performance properties, then explore our diverse 3D resin offering of multifunctional resins and 3D printing consulting services.

Do you need 3D printing consulting?

If you are fighting with your existing printer in a "black box" approach and feel that you need more control and understanding of the fundamental 3D printing variables affecting the performance, reliability and reproducibility of your work, or in case that you do not have a printer yet, or need a new one, and do not know yet which printer to buy? Then, you may consider ordering our 3D consulting and training services for helping you to choose the right 3D Printing System for your specific needs and goals, which include recommendations of all the required instrumentation, tools, materials, instructions and training for professional 3D printing: 3D printing consulting

Read About the importance of following 3Dresyns Instructions for Use "IFU" for getting optimum results!